PLCs and Industrial computers are indispensable for any industry that relies on automation. Considering that pretty much every major industry has some form of automation, it’s no wonder the demand for Industrial PCs and PLCs is always so high.

But what are industrial computers (IPC)? And how do they differ from PLCs that have served the automation industry for decades? What is the difference between a PC and an industrial PC? You’ll find the answers in this article.

PLC vs IPC Design and Hardware Comparison

PLC and IPC units are manufactured for industrial use, but their usage and capabilities vary quite a bit due to their hardware infrastructure. So, to understand the differences between the two, let us first unravel the basics of the two. Let’s find out the what is the difference between PLC and industrial PCs when it comes to hardware.

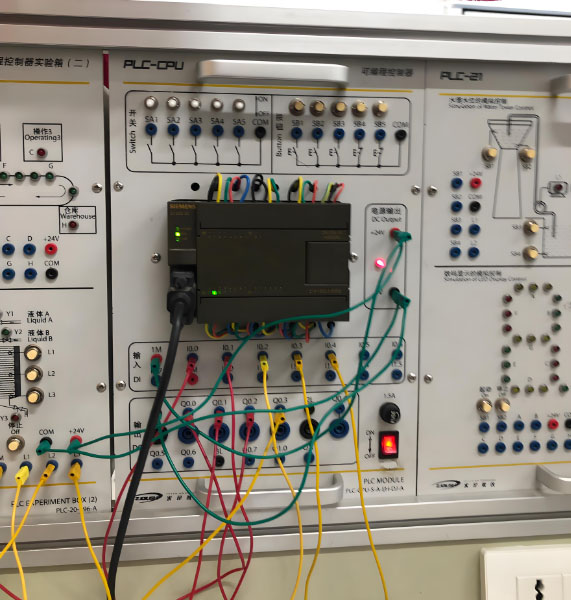

1. PLC (Programmable Logic Controller)

PLC stands for programmable logic controller. These are basically small-scale computers that can complete certain tasks based on outside input. PLC units basically revolutionized the automation industry by replacing its clunky predecessor, the relay banks.

Unlike relay banks, PLCs do not require endless tapestries of physical wires. A PLC unit usually has a microprocessor, a Memory chip, some integrated circuits for LAN connections, and a backup battery to ensure uninterrupted operation in case of power failure. It also runs on a unique operating system, unlike regular computers that can run Windows or Linux.

Depending on the usage and requirements, some PLC units also have screens and buttons for practical input. The unit also has a power supply and an output module that you can adapt for various tasks. It is much easier to reprogram a PLC unit than a relay bank, and they require far less space.

2. IPC (Industrial PC)

IPCs, or industrial PCs, are essentially tiny versions of your average modern computer. They can run Windows or Linux and support many programs. The only difference lies in the fact that these computers are much more durable and resistant to elements than your average home pc.

Industrial PCs, as you can imagine, are made for operating in an industrial environment. So, they are often resistant to high and low temperatures, vibrations, etc. While they function and operate exactly like your average home pc, their computational power varies wildly depending on your setup.

An Industrial PC also has the same core components as a regular PC, such as the CPU, Motherboard, memory, storage, and PSU. IPC units are usually much more compact than PLCs.

PAC (Programmable Automation Controller)

Performance Difference Between IPC Vs PLC

Besides the general differences in their operating structure and build style, PLC, and IPC units have several important performance differences as well. Let’s look into what is the difference between lPC and PC when it comes to performance.

1. Computation

Commutation power is perhaps the biggest defining difference between IPC and PLC units. PLC units replaced relay banks by introducing flexible and easily reprogrammable automation systems. While this system is very efficient, fast, and highly adaptable, it lacks the raw computing power of a modern computer.

That much is to be expected since PLC technology is almost half a century old at this point. From its inception not much has changed in the fundamental structure of this technology. That being said, for simple and less complex functions, a PLC unit will almost always outperform an IPC unit, mostly due to having a less convoluted system.

An Industrial PC, on the other hand, is a much more powerful beast. Modern-day IPC units are almost as powerful as regular full-scale computers, just with fewer bells and whistles. IPC units are becoming more popular because they can handle much more complicated commands and programs than a PLC unit.

2. Scalability

The biggest reason why industrial PCs are becoming so much more popular than PLCs is scalability. Both Industrial PCs and PLCs are mainly used for automating industrial facilities, machines, and other such components. But modern-day machines and their purpose are more prone to change.

So, relying on a fixed computing system that can only handle a single set of commands and output is hardly sufficient anymore. In short, PLCs are slowly becoming obsolete. While they are still very useful for simpler tasks, they are failing to make the cut for cutting-edge industries like robotics and vision projects.

It’s not that you can’t make a PLC do complicated tasks. But the problem lies in the fact that you’ll need to buy a lot more hardware to make it work. On the other hand, an industrial PC can easily scale its operations with simple software and program updates.

3. Operating System

What are the operating systems used in industrial PCs? Well, the operating systems of Industrial PC and PLCs differ quite a bit. Industrial PCs more or less use the same operating systems as your average PC. So, Linux and Windows are the go-to options.

PLCs, however, are too old to run any of those kernels. So, they use simpler, more discrete operating systems instead. While these are customizable, they don’t offer nearly as much flexibility as Windows or Linux.

The modern automation industry requires very complex computing power and enough memory to handle such tasks. Windows and Linux Operating systems are much better for handling these than the crude systems PLCs use.

4 Application Scenarios

Application Scenarios of IPC (Industrial Personal Computer)

- IPCs are suitable for scenarios that require high – precision measurement, complex data processing, and advanced control algorithms, such as high – end manufacturing and precision machining fields.

- IPCs also perform excellently in situations where data transmission and sharing with other computer systems or networks are needed.

Application Scenarios of PLC (Programmable Logic Controller)

- PLCs are widely used in various fields of the manufacturing industry, especially in discrete manufacturing processes (such as automobile manufacturing and machining). In these scenarios, PLCs can reliably accomplish various control tasks, such as material handling, assembly, and inspection on the production line.

- In addition, PLCs are commonly used in process control systems (such as in the chemical and metallurgical industries) to monitor and control various process parameters and equipment states.

PLC, PAC, IPC The Comparison is Shown in the Following Figure

| Function | PLC | PAC | IPC/PC Control |

| Processor | Specially designed gate array | General – purpose processor | Multi – core processor |

| Communication | Proprietary communication, limited standard protocols | Standard protocols | Most standard protocols, except for specialized hardware |

| Programming | Ladder diagram, or function block diagram | Multiple programming languages (IEC 61131 – 3) | IEC 61131 – 3, computer languages (C++, VB/VC, etc.) |

| Form Factor | Small/Medium, modular, rack – mounted | Medium/Large, rack – mounted | Connect field I/O via bus |

| Scalability | Low | Medium/High | Limited only by bus specifications |

| Software Cost | None/Low | Low/Medium | High |

| Hardware Cost | Low/Medium | Medium/High | High |

| Program Memory | Low/Medium | Medium/High | High, scalable |

| Motion Control | Good | Better | Best |

| Machine Vision | Good | Better | Best |

| Human – Machine Interface | Not applicable | Not applicable | Best |

IPCs and PLCs each have their own advantages in the field of industrial automation. IPCs excel in their powerful computing capabilities and flexibility, making them suitable for scenarios that require complex calculations and advanced control algorithms. On the other hand, PLCs have won wide recognition for their high reliability and stability, and they perform exceptionally well, especially in industrial control scenarios with high real – time requirements. When selecting appropriate control equipment, a comprehensive evaluation should be conducted based on specific application requirements and scenario characteristics.

Know More What is the difference between a industrial PC and an industrial panel PC?

Industrial PCs and industrial panel PCs have distinct characteristics. Industrial PCs are more general – purpose, often used as the central processing unit in industrial setups. They are like the “brains” that can be connected to multiple external devices and peripherals. They usually come in a chassis form factor, with space for expansion cards to adapt to different industrial needs, such as adding more network interfaces or high – performance graphics cards for applications like industrial automation monitoring systems.

Which One Should You Get?

Whether you need an Industrial Panel PC, Industrial PC or a PLC depends largely on the kind of task you want it to complete. Why is PLC better than PC? PLC systems are very fast and efficient for handling simple automation, while Industrial PCs are better for more complicated things.

Are industrial PCs more expensive than PLCs? Yes, they are, but there’s a caveat. While PLCs are cheaper upfront, they can get quite expensive if you want to upgrade them or scale your system. Industrial PCs, while having a higher initial cost, will let you upscale much easier with no additional hardware requirements.

Automation engineers also prefer Industrial PCs because it’s so much easier to program and maintain. Not to mention, they come with a lot more adaptability features that are crucial for fast-paced industries.

Conclusion

Hopefully, now you know what are industrial computers (lPC) and programmable logic controllers (PLC are). These are industrial processor units, predominantly used for automation, robotics, and other similar functions. If you want to know more about such tech or need a reliable place to source such products, feel free to contact us.

References:

What Is The Difference Between Industrial PC And Personal Computer?

https://www.candtsolution.com/news_events-detail/what-is-a-plc-the-difference-with-pc/

https://www.emdoorrugged.com/difference-between-industrial-pc-vs-plc.html

https://www.realpars.com/blog/plc-vs-pc

Penny

Web Content Writer

4 years of experience

This article is edited by Penny, the website content writer of COMPT, who has 4 years working experience in the industrial PCs industry and often discusses with colleagues in R&D, marketing and production departments about the professional knowledge and application of industrial controllers, and has a deep understanding of the industry and products.

Please feel free to contact me to discuss more about industrial controllers. sales@gdcompt.com