Product Quality Control

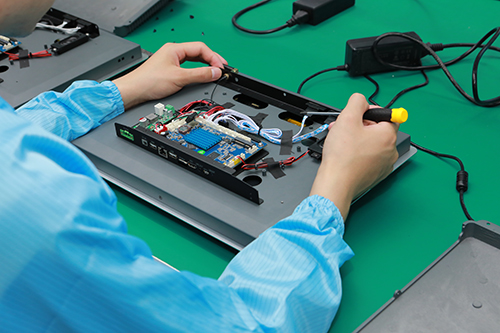

From meticulous material sourcing to precise assembly and strict quality inspections, every step is carefully orchestrated to ensure efficiency, consistency, and compliance with international standards.

Quality Control Process

Every product you received from Gdcompt has been detected by strict quality management standards. From research, production, assembly to shipment, each product undergone at least 10 rigorous tests to ensure its reliability. We provide industrial grade products and pursue customers' satisfaction.

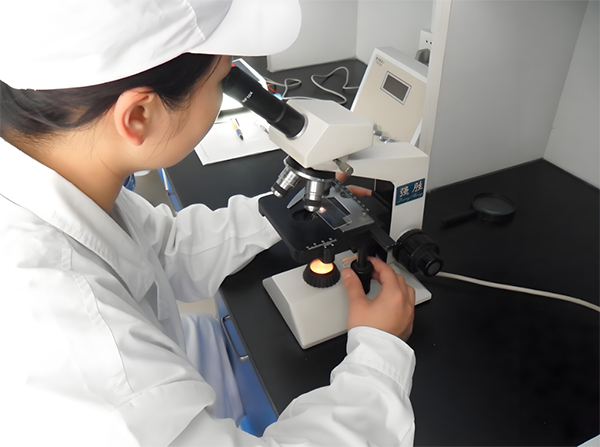

Incoming material inspection (IQC)

Inspection purpose: put an end to the aging loss caused by bad process and unqualified quality of renovated materials.

Conduct strict inspections and acceptance checks on purchased raw materials, spare parts, etc., to ensure that their quality meets the requirements. Establish a supplier evaluation and management system, select high-quality suppliers, and build long-term and stable cooperative relationships with them.

Consistent High Quality Products and Services

Quality Control and Assurance Leading to Constant Improvement

- Industrial aesthetic design

- Streamlined appearance design

- Independent research and development independent mold opening

- Stable performance and low power consumption

- Front panel waterproof design

- Flat panel up to IP65 waterproof standard

- GB2423 anti-vibration standard

- Added shock-proof EVA material

- Recessed cabinet installation

- 3mm tightly fitted to the embedded cabinet

- Fully enclosed dust-proof design

- Greatly improve the service life of the fuselage

- Aluminum alloy body

- Aluminum alloy die-casting integrated forming

- EMC/EMI Anti-interference standard Anti-electromagnetic interference