1.What exactly is an industrial computer?

An industrial computer (IPC) is a type of computer designed for industrial environments. They are typically capable of providing industrial automation over a wide range of temperatures, have enhanced durability, and contain specific features designed for industrial applications such as process control and data acquisition.

Integration

Designed for easy integration into larger systems:

Industrial computers are often designed to be modular and easy to integrate with other systems and equipment. This design allows them to become part of a larger automation system, thereby increasing overall efficiency and productivity. For example, in manufacturing, industrial computers can easily connect to various sensors and controllers on the production line to provide real-time data and control.

Ability to operate in harsh environments that ordinary PCs cannot cope with:

Industrial computers are able to operate reliably in environments where ordinary commercial PCs cannot function properly. These environments may include extremely high or low temperatures, high humidity, dust, vibration, and electromagnetic interference. Industrial PCs, through their rugged design and high-quality components, can operate stably in these environments for extended periods of time, ensuring uninterrupted production processes.

2. Extreme conditions

Withstand extreme temperatures, shock and vibration, dust, electromagnetic interference and other harsh conditions:

Industrial computers are designed to operate in extreme conditions. This includes withstanding extremely low to high temperature ranges (typically -40°C to 85°C), withstanding severe shock and vibration, and being able to function properly in dusty or particle-filled environments. They are also protected against electromagnetic interference, ensuring stable operation in high electromagnetic environments.

They usually have a rugged construction that is resistant to shock, dust, liquids and contamination:

The casing of industrial computers is usually made of robust materials such as aluminium alloy or stainless steel and is specially designed to protect against vibration and shock. The sealed design prevents dust and liquids from entering the interior and ensures that the internal electronic components are not contaminated. These features make industrial computers extremely reliable and durable in harsh environments.

3. Powerful Components

More powerful components than commercial PCs:

Industrial PCs typically use industrial-grade components that have been rigorously tested for greater reliability and durability. Their processors, memory, storage, and more have higher performance to handle complex industrial tasks. Industrial-grade hard drives and solid state drives (SSDs) offer higher read/write speeds and durability, ensuring fast data processing and secure storage.

High performance for demanding applications:

Equipped with high-performance processors and large amounts of memory, industrial PCs are capable of handling demanding industrial applications such as real-time data processing, machine vision and complex control algorithms. This allows them to excel in environments that require high computing power and stability, such as manufacturing automation, monitoring systems and industrial robotics applications.

4. Longer Lifespan

Typically last longer than commercial PCs:

Industrial PCs are designed and manufactured to a higher standard than commercial PCs and typically have a longer lifespan. They can operate reliably for years without interruption, which is critical for continuous production in industrial environments. Industrial PCs typically have a product lifecycle of at least 5-7 years, ensuring that frequent hardware replacements are not required during long-term projects.

Extended warranty and support services available:

Industrial computers usually come with extended warranties and professional technical support services. These services include quick hardware replacement, professional technical support, and customised maintenance plans. This kind of support is especially important for equipment used in critical industrial applications, ensuring that you can get back up and running quickly in the event of a problem, reducing downtime and lost production.

Industrial PCs provide reliable computing solutions for a wide range of industrial applications through their rugged design, robust performance and long life. They operate reliably in extreme environments and are essential for industrial automation and control systems.

2.Features of SIA Industrial PCs

a. Rugged construction:

SIA Industrial PCs are usually made of metal or alloy materials and have a robust casing to withstand physical shock and vibration. They are also dust-, water- and corrosion-resistant to withstand a variety of harsh industrial environments.

b. High Reliability:

Industrial PCs use high-quality components and rigorously tested hardware and software to ensure their stable operation for a long time. They are also usually equipped with fault detection and recovery mechanisms to minimise downtime and increase productivity.

c. Extended temperature range:

they can operate reliably over a wide range of temperatures, from extreme cold to extreme heat.

Vibration and shock resistant: They are designed to resist vibration and shock in industrial environments, such as from heavy machinery.

d. Dust and moisture resistance:

They have sealed enclosures that prevent dust and moisture from entering the system, which can damage sensitive components.

e. Long-term availability:

Industrial PCs typically have longer product lifecycles than consumer-grade computers, ensuring that they can be used in industrial applications for many years.

Expandability: Industrial PCs typically have multiple slots and interfaces so that users can add more feature cards and modules to meet their specific application needs.

f. Powerful Processing:

Industrial PCs are usually equipped with high-performance processors, large amounts of memory and high-speed storage to handle complex industrial tasks and data.

g. Easy to maintain and upgrade: Industrial PCs are often modular in design, allowing users to easily replace or upgrade their components. In addition, many industrial PCs are equipped with remote monitoring and management features so that users can easily monitor and maintain their systems.

3.Top 10 Features of COMPT’s Industrial PCs

Designed to meet the challenges of industrial environments, COMPT’s industrial computers have a variety of unique features that allow them to excel in a wide range of applications.

1. Fanless design

Avoid system problems caused by fan failure:

The fanless design improves system reliability and stability by avoiding potential failure problems associated with traditional fan systems. With no moving parts, wear and tear and maintenance requirements are reduced, extending the life of the unit.

Prevents the accumulation of dust and dirt, making it suitable for harsh environments:

The fanless design also prevents dust and dirt from accumulating inside the system, making it suitable for harsh industrial environments with lots of dust and dirt. This design ensures that the system maintains efficient operation in extreme environments and reduces dust-induced hardware failures.

2. Industrial-grade components are rugged and durable.

High reliability for 24/7 operation:

The use of highly reliable industrial-grade components that support 24/7 uninterrupted operation ensures consistent performance in mission-critical situations. Whether it’s manufacturing or monitoring systems, COMPT industrial computers keep running efficiently.

Adaptable to harsh environments and resistant to damage:

Industrial-grade components are rigorously tested to work stably in harsh environments such as extreme temperatures, vibration, and shock. Their rugged design makes them less susceptible to external environments, reducing maintenance and replacement costs.

3. Highly Configurable

Suitable for a wide range of tasks such as factory automation, remote data acquisition and monitoring:

COMPT industrial computers offer a wide range of configuration options for a variety of industrial applications, including factory automation, remote data acquisition and monitoring. Their flexible configurations enable them to meet the needs of different customers and provide efficient solutions.

OEM services such as customised branding, imaging and BIOS customisation are available:

COMPT also offers OEM services, which allow customers to customise the branding, system imaging and BIOS settings, etc. according to their needs. This customisation service ensures that customers get the most suitable solution for their specific application, improving the overall efficiency of the system.

4. Superior Design and Performance

Adaptable to wide temperature ranges and airborne particles:

Industrial PCs are designed to adapt to a wide temperature range and can operate stably in both extremely cold and hot environments. Additionally, the design takes into account airborne particulate matter to ensure that it can still function properly in dusty environments.

Designed for all-weather operation to meet unique application requirements:

Designed to meet the requirements of 24/7 operation, it is particularly suitable for applications that require continuous operation, such as monitoring systems, production line control, etc., ensuring reliable performance at all times.

5. Wide range of I/O options and additional features

Supports connection of a wide range of devices and sensors

COMPT industrial PCs feature a wide range of I/O interface options that support the connection of a variety of devices and sensors, such as serial, USB, Ethernet, etc., ensuring seamless integration with existing systems.

Customised features such as 4G LTE modem, hot-swappable drives, CAN bus, GPU, etc. are provided:

Depending on customer requirements, COMPT also offers a wide range of additional features such as 4G LTE modem, hot-swappable drivers, CAN bus, GPU, etc., which further extends the range of applications and functionality of the industrial PC.

6.Long Life Cycle

Supports long-term use with minimal hardware changes:

Industrial PCs are designed for a long lifespan and low frequency of hardware updates, which reduces the cost and inconvenience associated with frequent hardware replacement and ensures maximum return on customer investment.

Ensure applications are available for many years and support the latest chip architectures:

Supporting the latest chip architecture ensures that the system can still maintain leading performance and compatibility after many years of use, providing customers with long-lasting technical support and upgrade guarantee.

7. High Reliability

Wide temperature range:

COMPT industrial computers are able to operate reliably in a wide range of temperatures from extremely cold to extremely hot, which is suitable for applications in various extreme environmental conditions, such as outdoor equipment, industrial sites, and so on.

Resistant to Vibration and Shock:

Industrial computers are designed to withstand vibration and shock in industrial environments such as heavy machinery, ensuring stable operation in harsh environments and reducing unplanned downtime.

8. Dust and moisture resistant

A sealed enclosure prevents dust and moisture from entering the system, which can damage sensitive components:

Its sealed housing design effectively prevents dust and moisture from entering the system, protecting sensitive electronic components from damage and ensuring the long-term reliability and stability of the system.

9.Powerful processing power

Industrial PCs are typically equipped with high-performance processors, large amounts of memory and high-speed storage to handle complex industrial tasks and data:

Equipped with advanced processors, large amounts of memory and high-speed storage, they are capable of efficiently handling complex industrial tasks and large amounts of data to meet the performance needs of demanding applications.

10. Easy to maintain and upgrade

Industrial PCs are often modular in design, allowing users to easily replace or upgrade components:

The modular design allows users to easily replace or upgrade components, extending the life of the system and reducing maintenance costs.

With the above features, COMPT industrial computers provide reliable, efficient and flexible solutions for a variety of industrial applications, helping customers achieve optimal performance and maximum benefits in a variety of demanding environments.

4.What industries are industrial computers used in?

1. Manufacturing

Industrial computers play a key role in the manufacturing industry and their main applications include:

Controlling and monitoring factory machinery and tools:

Industrial computers are widely used to control and monitor all types of machinery and tools in factories to ensure the smooth running of production lines. By accurately controlling and monitoring the status of equipment, industrial computers can increase productivity and reduce the incidence of breakdowns.

Track inventory levels and ensure timely supply of raw materials:

Industrial computers can track inventory levels in real time, ensuring that raw materials are replenished in a timely manner to avoid production stoppages. With accurate inventory management, companies can optimise supply chain processes and reduce inventory costs.

Run quality control tests to ensure product quality:

Industrial computers are used to run a variety of quality control tests to ensure that the products produced meet strict quality standards. Through automated quality testing systems, industrial computers can quickly identify and eliminate non-conforming products, improving overall product quality.

2.Food and Beverage Processing

The food and beverage processing industry places very high demands on its equipment, and industrial computers are used in a variety of applications including:

Handling high speed data processing applications:

Food and beverage processing requires rapid processing of large amounts of data. Industrial PCs are equipped with high-performance processors and high-capacity storage to efficiently handle complex data analysis and monitoring tasks.

Easy integration into existing production lines:

Industrial PCs are designed to be flexible and can be easily integrated into existing production lines to improve overall productivity. Its multiple interfaces and communication protocol support make it easier to connect and collaborate with other devices.

Dust and water resistant design for easy cleaning and maintenance:

Food and beverage processing environments are dusty and moisture-intensive, and the Industrial PC is designed to be dust and water resistant to ensure stable operation in harsh environments. Additionally, they are easy to clean and maintain, maintaining the long-term stability and reliability of the equipment.

3.Medical environment

Industrial computers are also widely used in medical environments, and their main features and applications include:

Applications in medical equipment, patient monitoring, etc:

Industrial computers are widely used in various types of medical equipment and patient monitoring systems to provide stable and reliable computing and control functions to ensure the efficient operation of medical equipment and the safe monitoring of patients.

Provide medical grade monitor, touch screen and other special peripherals:

Medical environments have high requirements for monitors and touchscreens, and industrial computers can be equipped with medical-grade monitors and touchscreens to provide clear and reliable human-computer interaction interfaces that enhance the convenience and accuracy of medical operations.

Powerful storage and security features:

Industrial computers are equipped with powerful data storage and security features, capable of storing large amounts of medical data and ensuring data security and protecting patient privacy through encryption and access control.

4.Automotive industry

In the automotive industry, the main applications of industrial computers include:

Strong durability for automotive design and simulation:

Industrial PCs have strong durability and can run stably for a long time in harsh environments, making them suitable for demanding applications such as automotive design, simulation and testing.

Modular and expandable for easy integration into automotive production systems:

The modular design and strong scalability of industrial PCs allow them to be easily integrated into automotive production systems to support complex production and management tasks, improving overall productivity and flexibility.

5. Aerospace Industry

The aerospace industry requires a high degree of reliability and accuracy in equipment, where industrial computers are used in applications including:

Applications in flight data recorders, engine control and navigation systems:

Industrial computers are used in flight data recorders, engine control and navigation systems to provide reliable data processing and storage capabilities to ensure flight safety and efficient system operation.

Provide reliable computing power and accuracy:

Aerospace applications require powerful computing power and highly accurate data processing, and industrial computers are able to meet these stringent requirements through their advanced processors and precise algorithms to support complex aerospace missions.

6. Defence sector

The defence sector requires highly reliable equipment that operates in extreme conditions, where industrial computers are used in applications such as:

Applications in command and control, logistics management and sensor data processing:

Industrial PCs are used in critical applications such as command and control systems, logistics management, and sensor data processing, providing efficient computing and data processing capabilities to support complex military missions and decision-making.

Ability to operate in extreme conditions and high levels of ruggedness:

Industrial PCs are designed to be rugged and able to operate stably under conditions of extreme temperature, shock and vibration, ensuring that they can still provide reliable performance in harsh military environments and support the smooth running of defence missions.

In summary, with their high reliability, powerful performance and flexible configurations, industrial computers are widely used in a variety of fields such as manufacturing, food and beverage processing, medical environments, automotive, aerospace and the defence sector, providing strong technical support and solutions for various industries.

5.Differences between commercial and industrial computers

a. Design and construction

Commercial computers:

Commercial computers are typically used in office and home environments and are designed with a primary focus on aesthetics and user-friendliness. They are usually housed in plastic cases and lack additional protection. Commercial computers are more commonly built and cannot withstand the rigours of harsh environments.

Industrial computers:

Designed for industrial environments, industrial computers are rugged and durable. They are usually housed in metal cases with shock, dust, and water-resistant designs. Industrial computers are able to operate stably in harsh environments with extreme temperatures, vibration, and humidity.

b. Components and Performance

Commercial computers:

Business computers come with components that are usually standard consumer-grade hardware for everyday office and entertainment use. They have average processor, memory, and storage performance to meet the needs of the average user.

Industrial computers:

Industrial computers use high-performance industrial-grade components capable of handling complex industrial applications and tasks. They are typically equipped with powerful processors, high-capacity memory and high-speed storage and are suitable for demanding data processing and real-time control tasks.

c. Longevity and Reliability

Commercial computers:

Commercial computers have a relatively short lifespan, usually between 3-5 years. They are designed primarily for short-term use and lack the ability to operate stably for long periods of time.

Industrial Computers:

Industrial computers have a long lifespan, usually capable of stable operation for 7-10 years or more. They are designed for long, continuous operation with high reliability and stability and are suitable for 24/7 working environments.

d. Customisation and scalability

Commercial computers:

Commercial computers have weak customisation and limited scalability. Users can only upgrade and replace a small number of components, such as memory and hard drives.

Industrial Computers:

Industrial computers are highly customisable and scalable. They can be customised according to specific application requirements, including interfaces, I/O modules, communication modules, and so on. In addition, industrial computers support a variety of expansion slots and modular design, making it easy for users to upgrade and replace components.

e.Environmental adaptability

Commercial Computers:

Designed for use in stable indoor environments, commercial computers cannot function properly in harsh industrial environments. They are sensitive to environmental factors such as temperature, humidity and vibration, and are susceptible to external factors.

Industrial Computers:

Industrial computers are designed to adapt to a variety of extreme environments and are able to operate stably in high and low temperatures, humidity, vibration and other environments. They are dustproof, waterproof, and vibration-proof, making them suitable for use in a variety of harsh industrial environments.

f. Support and Services

Commercial computers:

Commercial computers typically come with limited warranty and support services, primarily for personal and small business users. Warranties are typically 1-3 years and support services are relatively basic.

Industrial Computers:

Industrial computers typically offer long warranties and professional technical support services. The warranty period can be up to 5-10 years, and support services include on-site maintenance, remote support and customised solutions to ensure the stability and continuity of industrial applications.

In summary, there are significant differences between commercial and industrial computers in terms of design, components, performance, longevity, customisation, environmental adaptability and support services. Industrial computers are the devices of choice for industrial applications due to their high reliability, robust performance, and ability to adapt to harsh environments.

6. What is an industrial workstation?

Industrial workstations are high-performance computer systems designed for industrial environments, typically used for complex computing tasks and high-demand industrial applications. They combine the ruggedness of industrial computers with the powerful computing capabilities of commercial workstations to deliver exceptional performance and reliability in demanding environments.

Features of Industrial Workstations

High-performance computing:

Industrial workstations are typically equipped with the latest multi-core processors, high-capacity memory, and high-speed storage capable of handling complex data calculations and graphics rendering tasks. This makes them ideal for applications that require high computing power, such as CAD (computer-aided design), CAM (computer-aided manufacturing), data analysis and simulation.

Rugged:

Compared to commercial workstations, industrial workstations have a more rugged design that allows them to operate stably in harsh environments such as extreme temperatures, vibration, dust and humidity. They are usually housed in metal enclosures that are dust, water and vibration resistant.

Long life and high reliability:

Industrial workstations are designed to operate for long, continuous periods of time and are usually capable of providing stable service for 7-10 years or more. Their components are rigorously screened and tested to ensure high reliability and stability in industrial environments.

Rich I/O interfaces:

Industrial workstations are usually equipped with rich I/O interfaces to support the connection of a wide range of external devices and sensors, such as USB, RS232, RS485, Ethernet, CAN bus and so on. They can also be customised to add special interfaces and modules as required.

Expandability:

Industrial workstations are highly scalable and can be upgraded and expanded by users according to specific application requirements. They usually support multiple expansion slots and modular design, making it easy to add additional hard drives, memory, graphic cards, etc.

Professional software support:

Industrial workstations are usually pre-installed or compatible with professional industrial software and operating systems, such as real-time operating systems (RTOS), industrial automation software and monitoring systems to meet the needs of different industrial applications.

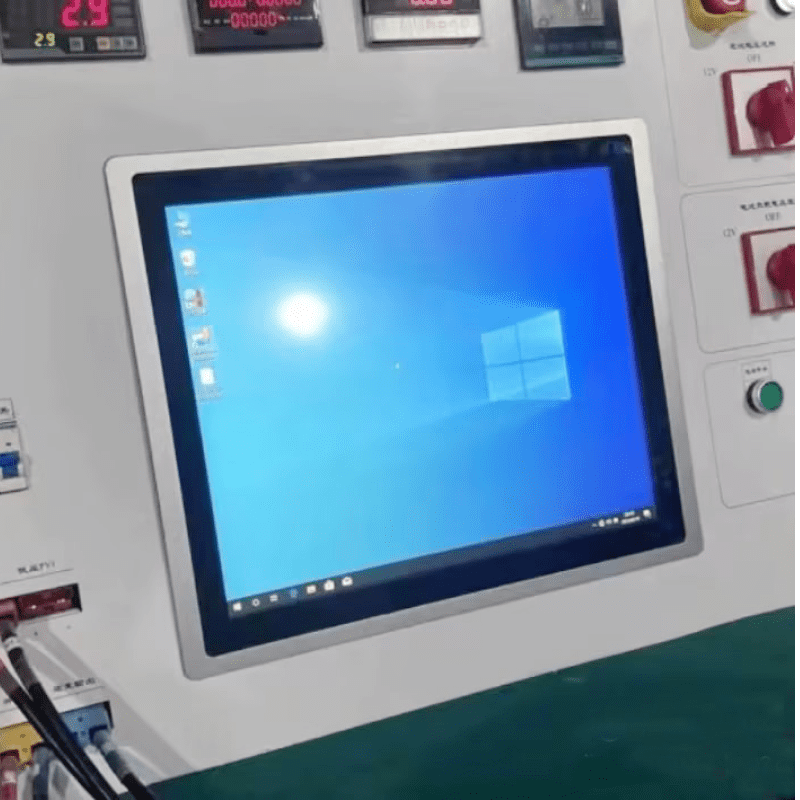

7. What is a “Panel PC”?

A panel computer (Panel PC) is an industrial computing device with an integrated touchscreen monitor and computer hardware. They are usually designed as compact, all-in-one devices that can be mounted directly on machines, control cabinets or walls, and are widely used in areas such as industrial automation, smart manufacturing, medical devices and retail.

Features of panel computers

All-in-one design:

Panel computers integrate the display and computer hardware into a single device, reducing the footprint and the need for complex wiring. This design not only simplifies the installation process, but also makes for a more compact and tidy system.

Touchscreen capabilities:

Panel computers are often equipped with touchscreens that support resistive, infrared, or capacitive touch technology, enabling users to operate directly from the touchscreen. This improves ease of operation and efficiency, and is particularly suitable for industrial control and human machine interface (HMI) applications.

Ruggedness:

Panel computers typically have a rugged construction that allows them to operate in harsh industrial environments. They are typically designed to be dust-, water-, shock-, and scratch-resistant, meeting IP65 or higher protection ratings to ensure reliable operation of the equipment in high-humidity, high-dust, and high-vibration environments.

Multiple mounting options:

The panel computer supports a variety of mounting methods, such as embedded mounting, wall mounting and desktop mounting, adapting to different application scenarios and installation needs. Flush mounting is especially suitable for use in equipment or control cabinets with limited space.

Flexible I/O interface:

Panel computers are usually equipped with a wealth of I/O interfaces, such as USB, serial (RS232/RS485), Ethernet, HDMI/VGA, etc., which make it easy to connect various external devices and sensors to meet the needs of different applications.

High performance processing:

Panel computers are equipped with powerful processors and high-capacity memory to cope with complex computing tasks and real-time data processing. They usually adopt low-power, high-performance processors to ensure stable operation under high loads.

Customisation options:

Panel computers can be customised to meet the requirements of specific applications, such as customising the size, interface, touch screen type and casing material. For example, certain industries may require antimicrobial enclosures or higher levels of protection.

8. can any type of pc be used for shop floor measurement and spc applications?

Not any type of PC can be used for shop floor measurement and statistical process control (SPC) applications. Shop floor environments are often harsh and can have conditions such as high temperatures, dust, vibration, and humidity where ordinary commercial PCs may not operate reliably. Therefore, choosing the right type of PC for these applications is critical.

Advantages of industrial PCs for shop floor measurement and SPC applications

1. Ruggedness

Industrial PCs have a rugged casing and internal structure that resists vibration, shock, and other physical damage in the shop floor.

The hermetically sealed design prevents the ingress of dust and moisture, ensuring the reliability of the device in harsh environments.

2. Wide Temperature Range

Industrial PCs are designed to operate properly in extreme temperatures, both high and low, and maintain stable performance.

3. High Reliability

Industrial PCs typically support 24/7 operation, which is especially important for SPC applications that require constant monitoring and data collection. High-quality components and strict manufacturing standards ensure long life and high reliability.

4. Rich I/O interfaces

The Industrial PC provides a variety of I/O interfaces for easy connection to various measuring devices and sensors, such as thermometers, pressure sensors, displacement sensors, etc.

It supports various communication interfaces such as RS-232/485, USB, Ethernet, etc., which is convenient for data transmission and device interconnection.

5. Powerful processing capability

Equipped with a high-performance processor and large-capacity memory, the industrial PC is able to quickly process a large amount of measurement data and perform real-time analysis and storage.

It supports complex SPC software to help enterprises carry out quality control and process optimisation.

Choosing the right industrial PC

The following factors should be considered when selecting an industrial PC for shop floor measurement and SPC applications

6. Environmental Adaptability

Ensure that the PC can adapt to environmental conditions such as temperature, humidity and dust in the workshop.

If there is strong electromagnetic interference on the shop floor, you also need to select a PC with electromagnetic shielding capabilities.

7. Performance requirements

Select the appropriate processor, memory and storage configuration for the specific measurement and SPC application requirements.

Consider future expansion needs and select a PC with scalability.

8. Interface and Compatibility

Ensure that the PC has the required I/O interfaces to connect all necessary measurement devices and sensors.

Ensure that the PC is compatible with existing software and hardware systems.

Overall, ordinary commercial PCs may not be able to meet the special needs of shop floor measurement and SPC applications, while industrial PCs are ideal for these applications due to their ruggedness, high reliability and rich interfaces. In the actual selection, you need to choose the right industrial PC model and configuration according to the specific application scenarios and requirements

9. How to choose the best industrial computer

Choosing the best industrial computer requires a combination of factors, including performance benchmarks, available power supply, deployment environment, and specific application requirements. Below are some key steps and recommendations to help you choose the best fanless industrial computer.

1. Determine Performance Needs

Application requirements: First, identify the specific applications for which the industrial computer will be used, such as data acquisition, process control, and monitoring. Different applications have different processor, memory and storage requirements.

Performance Benchmark: Based on the application requirements, select the appropriate processor (e.g., Intel Core, Xeon, AMD, etc.), memory capacity, and storage type (e.g., SSD or HDD). Ensure that the computer is capable of running the required software and processing tasks efficiently.

2. Consider power requirements

Power supply: Determine the type of power supply and available power capacity in the deployment environment. Some industrial computers require specific power inputs, such as 12V, 24V DC, or standard AC power.

Power supply redundancy: To improve system reliability, choose industrial computers with redundant power supply designs to ensure normal operation in the event of a power failure.

3. Evaluate the deployment environment

Temperature range: Consider the ambient temperatures in which the industrial computer will operate, and select a device that is capable of stable operation in extreme temperatures.

Dust and Water Resistance: If the deployment environment has dust, moisture or liquids present, choose an industrial computer with a dust and water resistant design, such as an IP65 rated enclosure.

Vibration and shock resistant: In environments where vibration or shock exists, choose industrial computers with vibration and shock resistant designs to ensure their stability.

4. Determine the interface and expandability

I/O interfaces: According to the number of devices and sensors to be connected, select an industrial computer with sufficient I/O interfaces, including USB, RS-232/485, Ethernet, CAN bus, etc.

Expansion capability: Considering possible future needs, choose industrial computers with expansion slots (e.g., PCIe, Mini PCIe, etc.) to facilitate subsequent upgrades and expansion of functionality.

5. Select fanless design

Fanless design: Industrial PCs with fanless design avoid system problems caused by fan failure and reduce the accumulation of dust and dirt, making them suitable for use in harsh environments.

Heat dissipation performance: Ensure that the fanless industrial computer you choose has a good heat dissipation design, such as aluminium alloy heat sinks and optimised heat transfer paths, to maintain stable operation of the equipment under high loads.

6. Evaluate suppliers and after-sales service

Supplier reputation: Choose a reputable industrial computer supplier to ensure product quality and technical support.

After-sales service: Understand the after-sales service and warranty policy provided by the supplier to ensure timely support and maintenance in case of equipment problems.

11.Who we are?

COMPT is China based industrial PC Manufacturer With over 10 years of experience on customization development and production, We can provide custom-made solutions and cost-effective industrial Panel PC / Industrial Monitor for our global clients, which could be widely used on industrial control sites, automated intelligent manufacturing etc. The installation support Embedding and VESA mounting .Our market include 40% EU and 30% US, and 30% China.

What we producing:

Our products include below for selection,all with EU and U.S testing certificate:

We provide Full size range from 7” – 23.6 ” PC and monitor with various customized interfaces which could meet all clients’ application Scenarios.

I am looking forward to your prompt enquiry by return.

Penny

Web Content Writer

4 years of experience

This article is edited by Penny, the website content writer of COMPT, who has 4 years working experience in the industrial PCs industry and often discusses with colleagues in R&D, marketing and production departments about the professional knowledge and application of industrial controllers, and has a deep understanding of the industry and products.

Please feel free to contact me to discuss more about industrial controllers. sales@gdcompt.com