Industrial Grade PC Definition

An industrial grade PC (IPC) is a rugged computer designed for use in industrial environments with increased durability, the ability to operate in a wide range of temperatures, and features tailored to industrial applications such as process control and data acquisition. Commonly used in applications such as manufacturing, building automation, smart agriculture and logistics centres. Industrial computers are computers used for industrial purposes (including the production of goods and services) in a form factor between a small desktop and a server rack. Industrial computers have high standards of reliability and accuracy, are typically more expensive than consumer electronics, and often use complex instruction sets (e.g., x86) rather than simplified instruction sets (e.g., ARM).

With the rapid growth of the Internet of Things (IoT) and more and more devices being installed in remote and hostile environments, reliable hardware is becoming more and more important.IT failures can have a direct and significant impact on a company’s bottom line. As a result, ruggedised hardware is required. industrial grade computers, unlike regular consumer computers, are reliable solutions designed for harsh environments.

Industrial computers typically have the following features:

- Fanless and ventless design

- Able to withstand harsh environments

- Highly configurable

- Rich I/O options

- Long life cycle

Industrial PC History

- 1. IBM released the 5531 industrial computer in 1984, probably the first “industrial PC”.

- 2. On 21 May 1985, IBM released the IBM 7531, an industrial version of the IBM AT PC.

- 3. Industrial Computer Source first offered the 6531 industrial computer in 1985, a 4U rack-mounted industrial computer based on a cloned IBM PC motherboard.

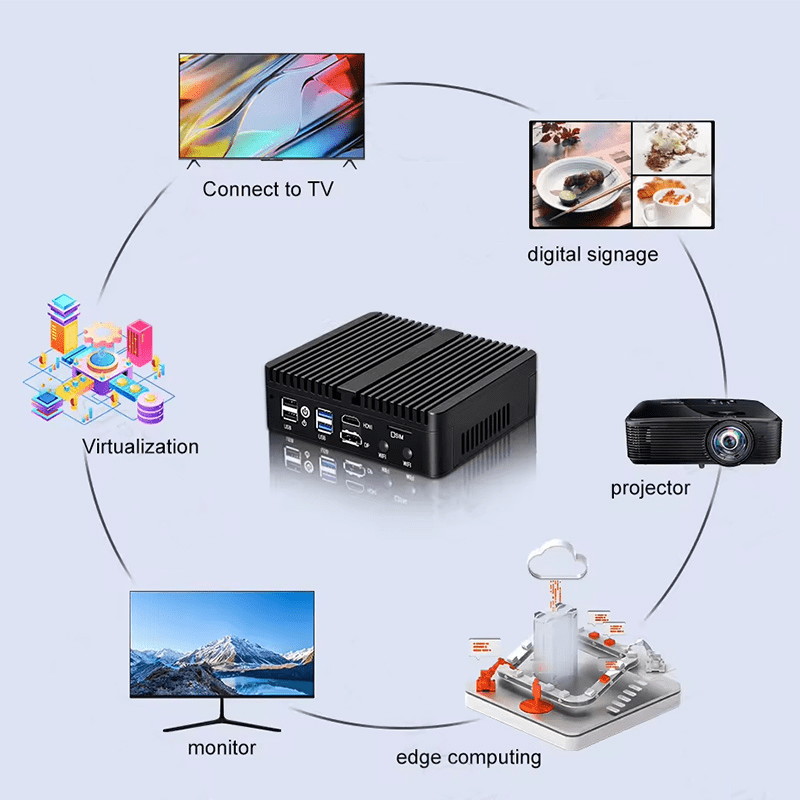

Industrial PC Solution

- Manufacturing: Control and monitor factory machinery and machine tools to ensure smooth operation of production lines, inventory tracking and quality control testing.

- Food and Beverage Processing: High-speed data processing and seamless integration with production lines, adapting to stringent hygiene requirements and production environments.

- Medical environments: for medical devices, patient monitoring and medical records management, providing reliability, safety and flexibility.

- Automotive: For automotive design, simulation and vehicle diagnostics with durability and thermal management benefits.

- Aerospace: for flight data recording, engine control and navigation systems, ensuring data processing power and system stability.

- Defence: for command and control, logistics management and sensor data processing, offering a high degree of flexible configuration and operational reliability.

- process control and/or data acquisition. In some cases, the Industrial PC is used only as a front-end to another control computer in a distributed processing environment.

Top 10 Features of Industrial PC

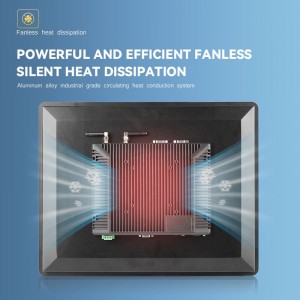

1. Fanless Design

Commercial PCs are typically cooled using internal fans, which are the most common point of failure in computers. As the fan draws in air, it also draws in dust and dirt, which can build up and cause heat problems that can lead to system throttling or hardware failure.COMPT Industrial PCs, on the other hand, use a proprietary heatsink design that conducts heat away from the motherboard and other sensitive internal components into the chassis and emits it into the surrounding air. This is especially important in harsh environments filled with dust, debris or other airborne particles.

2. Industrial Grade Components

Industrial PCs are built with industrial grade components designed to provide high reliability and maximum uptime. These components are designed to operate 24/7, even in harsh environments, whereas consumer desktop PCs can be damaged or even destroyed.

3. Highly Configurable

Industrial PCs can perform many different types of tasks, including factory automation, remote data collection, and monitoring.COMPT’s systems are highly configurable to meet your project needs. In addition to reliable hardware, we offer OEM services such as custom branding, image and BIOS customisation.

4. Superior Design and Performance

Industrial computers are designed to cope with harsh environments that include wider operating temperature ranges and airborne particulate matter.COMPT Industrial PCs are designed for 24/7 operation to meet the needs of unique applications. We offer a broad portfolio of hardware ranging from industrial fanless PCs to rugged computers that operate over a wide temperature range and are resistant to shock and vibration.

5. Rich I/O Options and Additional Functions

To effectively communicate with sensors, PLCs, and legacy devices, industrial PCs offer a wealth of I/O options and add-on features. Industrial PCs eliminate the need for adapters or adaptors because they provide I/O functions suitable for applications outside of the traditional office environment.

6. Long Life Cycles

Industrial PCs typically have a longer lifespan than commercial PCs and often come with extended warranties and support services. Not only do Industrial PCs have higher reliability and uptime, they also have an embedded lifecycle and are available for long periods of time. Industrial PCs allow companies to standardise on computers without major hardware changes for up to five years. Long lifecycles mean your applications are supported and available for many years.

7. Integration

Industrial PCs integrate seamlessly into larger systems and can operate in harsh environments that ordinary computers cannot.

8. Extreme Conditions

Industrial computers can withstand extreme temperatures, shock, vibration, dust and electromagnetic interference. They typically feature rugged construction, dust-proof design, sealed enclosures that keep out liquids and contaminants, and resistance to electromagnetic interference.

9. Powerful Components

IPCs often contain more powerful components than commercial PCs, providing high performance for demanding applications. From small embedded computers to large rackmount systems, IPCs are available in a variety of form factors to meet the specific needs of industrial users.

10. Customisable

They provide extended I/O and communication capabilities to support industrial automation applications. Although industrial PCs are diverse, they share the common goal of providing reliable computing power in demanding environments.

Business Computing Overview

Definition and Characteristics

1. Mainly used in offices, education and other controlled environments, usually with fan cooling design.

2. Mainstream applications include Internet access, office software use, data analysis, etc.

Design and Components

1. Conventional aluminium alloy and plastic casing, lightweight design, fan design for heat dissipation.

2. Suitable for standard office temperature and dry environment.

Applicable Scenarios

Daily applications in controlled environments such as offices, schools, and personal use.

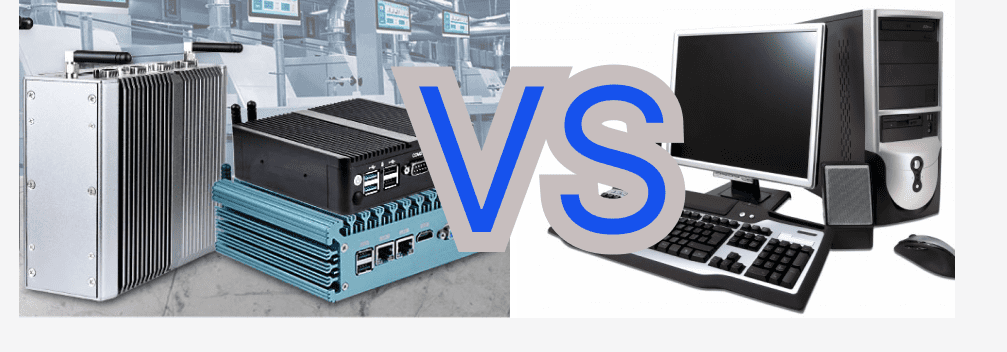

Industrial computers vs. commercial computers

Mechanical structure and thermal design

1. Industrial computer adopts fanless design and integrated structure, strong anti-vibration and anti-dust and water ability.

2. Commercial computers use fan cooling, lightweight structure to adapt to the standard office environment.

Environmental adaptability

1. Industrial computers can work in extreme temperatures, high humidity and dusty environments.

2. Commercial computers are adapted to standard indoor temperatures and dry environments, and do not have protection level requirements.

Applicable scenes and applications

1. Industrial computers are widely used in manufacturing automation, security monitoring, mining and military applications.

2.Business computers are mainly used for office, education, daily Internet access and data processing.

Functions and Hardware.

Industrial computers and commercial computers have similar functions in receiving, storing and processing information, and the hardware components include motherboard, CPU, RAM, expansion slots and storage media.

Durability

Shock and High Temperature Resistance: Designed for use in harsh, high temperature and high vibration environments, industrial computers are able to withstand shocks of up to 5G and high vibrations of 0.5G to 5m/s.

Resistant to Dust and Humidity: Industrial computers are equipped with cooling fans with special filters to ensure a clean and ventilated interior that is resistant to dust and humidity, which commercial PCs are not.

IP rating: Industrial computers offer IP protection, e.g. Beckhoff’s IP65 standard for protection against dust and moisture, whereas commercial PCs usually do not.

Electromagnetic Interference: Electromagnetic interference, common in industrial environments, can lead to communication failures and voltage fluctuations between devices. Industrial computers are designed with good isolation and voltage stabilisation features to ensure system stability.

Performance and Reliability

Efficient Operation: Industrial computers are capable of running powerful automation software and controlling complex applications, ensuring high performance and reliability to enhance operational efficiency.

Continuous operation: The rugged construction and advanced power support of industrial computers ensure stable operation over long periods of time, avoiding costly downtime.

Scalability and Long-Term Availability

Scalability: Industrial computers are more scalable than commercial PCs, supporting technological innovations and long-running applications, and reducing the difficulty of replacing commercial components that are no longer in production.

Spare parts and upgrades: Industrial computers are easier to maintain and upgrade over their lifetime, thanks to guaranteed long-term supply and spare parts availability.

Cost of ownership

Despite the higher initial investment, the total cost of ownership of industrial computers is much lower in the long term than conventional commercial PCs, which cannot withstand the rigours of industrial environments and require frequent repair or replacement.

High-end design and performance

Product choice: Beckhoff offers a wide range of industrial PC solutions, including multi-touch panel PCs and control cabinet PCs, for different control system installations.

Material Choice: Aluminium and stainless steel display options are available to meet the installation requirements of different environments.

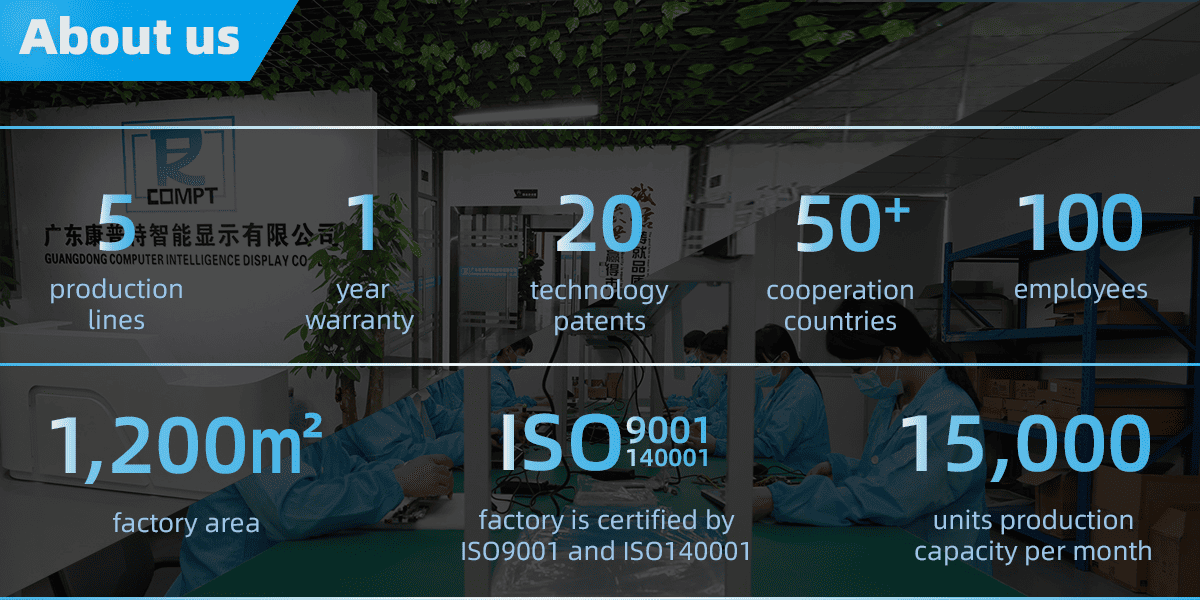

COMPT is your industrial PC of choice

The choice of an industrial PC is crucial for many businesses, and COMPT may be a very good choice. Here are some possible reasons why:

Reliability:

Industrial PCs are often required to operate in harsh environments, and COMPT’s products are likely to have a high degree of reliability and durability, and be able to operate stably in environments with high temperatures, low temperatures, dust, vibration, and more.

Performance:

COMPT’s industrial PCs may have powerful processing capabilities to meet the needs of a variety of complex industrial applications, including data acquisition, real-time control and automation.

Scalability:

Industrial PCs often need to be connected to a variety of peripherals and sensors, and COMPT’s products may offer a wealth of interfaces and expansion slots to facilitate expansion and upgrades as needed.

Customisation:

Different industrial applications have different needs, COMPT may offer customisation services and can provide tailor-made solutions according to customers’ specific requirements.

Support and Service:

Good after-sales support and service is very important for the use of industrial PCs. COMPT may provide comprehensive technical support and after-sales service to ensure that problems encountered by users in the process of use can be resolved in a timely manner.

If you have specific needs or questions, you can provide more detailed information, I can help you better evaluate whether COMPT industrial PC is suitable for your application scenario.

Penny

Web Content Writer

4 years of experience

This article is edited by Penny, the website content writer of COMPT, who has 4 years working experience in the industrial PCs industry and often discusses with colleagues in R&D, marketing and production departments about the professional knowledge and application of industrial controllers, and has a deep understanding of the industry and products.

Please feel free to contact me to discuss more about industrial controllers. sales@gdcompt.com