Capacitive touch screen is a touch screen technology that works by utilizing the current sensing of the human body. It is mainly composed of four layers of composite glass screen, including the inner surface and interlayer each coated with a layer of ITO (nano indium tin metal oxide), the outermost layer is a thin layer of silica glass protective layer. Capacitive touchscreens are widely used in smartphones, tablet PCs, industrial equipment and other areas of advanced touch technology.

Unlike the traditional resistive touch screen, capacitive touch screen realizes input by sensing the change of electric field when the user touches the screen without physical pressure, providing more accurate and fast response.COMPT self-developed and produced industrial panel pc or monitor adopts capacitive touch screen because of its high light transmittance, fast response speed, long service life and so on.

The working principle of capacitive touch screen

Through the finger and the screen surface of the coupling capacitance, when the finger touch in the metal layer, will be sucked from the touch point of a very small current, this current from the four corners of the touch screen electrodes out of the four electrodes flowing through the four electrodes of the current and the finger to the four corners of the distance is proportional. The controller derives the position of the touch point through the precise calculation of the ratio of these four currents.

Capacitive touch screen class

Surface capacitive touch screen

this kind of touch screen has simple structure and low price, but it is difficult to realise multi-touch.

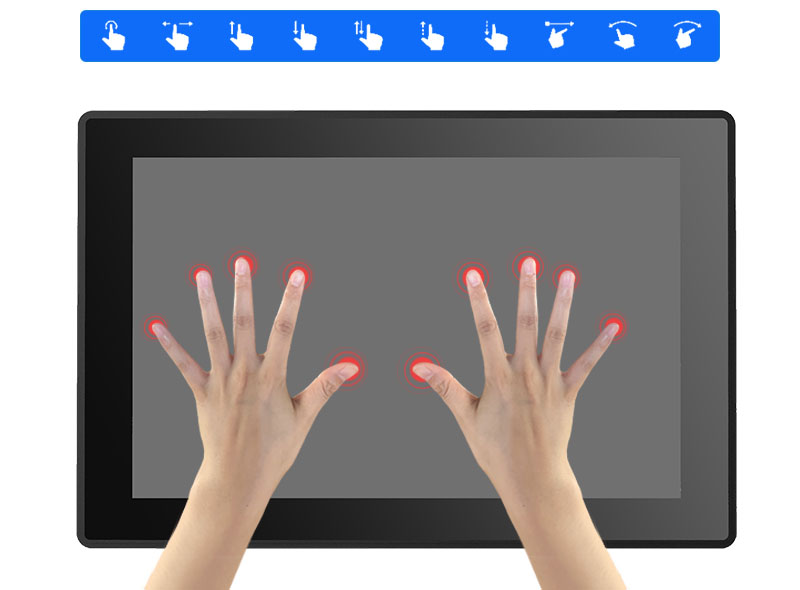

Projected capacitive touch screen

this kind of touch screen has the function of multi-finger touch control, by increasing the electrode of mutual capacitance to achieve multi-touch.

How does capacitive touch screen work?

Capacitive touch screen uses the conductivity of the human body, through the perception of changes in the electric field on the surface of the touch screen to achieve the operation. When a finger touches the screen, it will change the electric field distribution on the surface of the touch screen, and the electrodes on the touch screen detect these changes and pass the signal to the controller, thus realising touch input.

Application Areas of Capacitive Touch Screens

Capacitive touchscreens are widely used in a variety of industries, including smartphones and tablets: to provide precise multi-touch operation, industrial equipment: such as industrial control systems and automation equipment, which are widely used due to their high durability and accuracy.

Medical devices: for medical instruments and self-service health testing equipment.

Retail and self-service terminals: e.g. self-service ordering machines, self-service enquiry machines, etc.

How to clean the capacitive touch screen?

To clean the capacitive touch screen, use a soft microfibre cloth dipped in a small amount of water or a special cleaner to gently wipe the screen, avoid using cleaners containing alcohol or solvents that may damage the surface of the screen. Avoid using hard objects to scratch the touchscreen to maintain the clarity and durability of the screen.

Which capacitive device is best suited?

Depending on your business needs, it is important to choose the right capacitive device. For example, in the retail and service industry, kiosks and ordering machines often require highly sensitive touchscreens; in the industrial control sector, capacitive touchscreens that are highly durable and can operate in harsh environments may be required.

Contact Points + Importance of Capacitive Touch Screens

The contact points of a capacitive touch screen are the points on the surface of the touch screen that can be sensed. The number and distribution of contact points directly affects the sensitivity and accuracy of the touch screen. A high-quality capacitive touchscreen provides more accurate inputs, especially critical in multi-touch and gesture operations.

How to choose a capacitive touch screen?

Touch accuracy: Make sure the touch screen supports the required accuracy, especially in industrial and medical devices.

Environmental Adaptability: Choose a capacitive touch screen that adapts to different temperatures and humidity depending on the environment in which it will be used.

Cost vs. performance: Balance cost and performance to ensure that application requirements are met.

Advantages of Capacitive Touch Technology

Fast Response

The touch response is very fast and is suitable for devices that require real-time operation.

High durability

Capacitive touchscreens typically have a long lifespan and can work stably in environments with high-frequency use.

Multi-touch support

able to support multi-finger simultaneous operation, suitable for modern application needs. in the device.

Environmental Adaptability

Choose a capacitive touch screen that adapts to different temperatures and humidity depending on the environment in which it will be used.

Cost vs. performance

Balance cost and performance to ensure that application requirements are met.

Well, this is all about capacitive touch screen today, because COMPT’s industrial panel computer also uses capacitive touch screen, mainly because it has the following advantages:

1. More sensitive and accurate: fast touch response, support multi-touch, improve operational efficiency.

2. More durable: the glass surface is wear-resistant and anti-scratch, resistant to dust, oil and water droplet effects.

3. Clearer: High light transmission rate, better display effect, suitable for high brightness environment.

4. Longer life: no physical sensing parts, longer service life than resistive screen.

5. Customisable glove touch: to adapt to the needs of industrial field operations.

Comprehensive view, capacitive touch screen is more in line with industrial automation, intelligent manufacturing and other application scenarios. If you want to know more about industrial panel pc capacitive touch screen, welcome to contact us.

Penny

Web Content Writer

4 years of experience

This article is edited by Penny, the website content writer of COMPT, who has 4 years working experience in the industrial PCs industry and often discusses with colleagues in R&D, marketing and production departments about the professional knowledge and application of industrial controllers, and has a deep understanding of the industry and products.

Please feel free to contact me to discuss more about industrial controllers. sales@gdcompt.com