1. What are Infrared Touch Screens?

Infrared Touch Screens (IR Touch Screens) are a contactless touch technology that uses the principle of infrared sensing for touch interaction. Unlike capacitive or resistive touchscreens, IR touchscreens do not rely on physical pressure or changes in electrical current, but instead use optical sensors to detect the touch position, resulting in high durability and wide applicability.

2. How Infrared Touch Screens Work

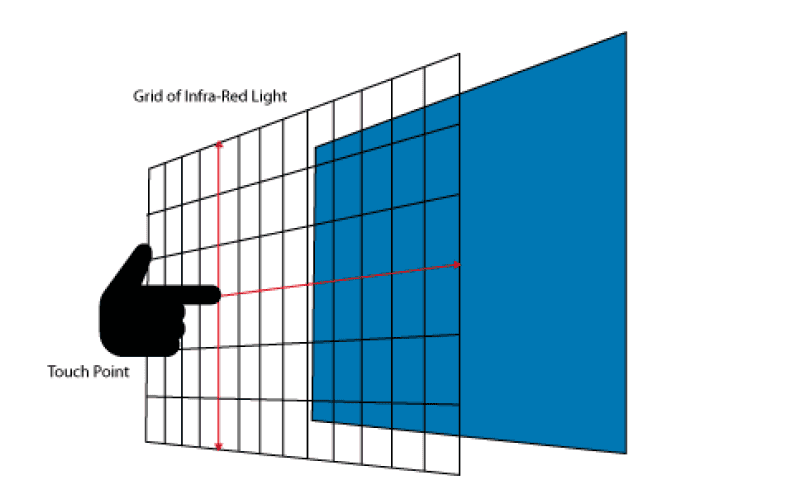

Infrared Touch Screens create an invisible infrared grating through infrared emitters and receivers mounted on the edge of the screen. When the user’s finger or object (such as a stylus) touches the screen, it will block certain infrared beams, resulting in a signal interruption at specific coordinates. The system detects these changes through the optical sensors and calculates the position of the touch point to achieve precise touch operation.

3. Key Factors in Evaluating Infrared Touch Screens

The following factors need to be considered when choosing the right Infrared Touch Screens:

Screen size: Suitable for medium to large size displays (commonly 32’ and above).

Number of Touch Points: Supports 2, 4, 10 or more multi-touch points.

Response Speed: High quality infrared screens can achieve <10ms touch response.

Environmental Adaptability: Suitable for outdoor, bright light exposure or industrial environments.

Durability: No physical contact wear and tear, suitable for high-frequency use scenarios.

4. Advantages and Limitations of Infrared Touch Screens

✅ Advantages:

High durability: no physical wear and tear, suitable for public and industrial environments.

Large size compatibility: Can be applied to displays from 32‘’ to over 100‘’.

Multi-touch: Supports simultaneous operation by multiple people to enhance the interactive experience.

High light transmittance: no glass cover, clear picture quality without affecting the display effect.

Low Maintenance: No capacitive layer or film, no need for frequent calibration.

⚠️ limitations:

Affected by ambient light: strong direct light may affect touch accuracy.

Not suitable for small devices: difficult to apply to screens under 10’.

Requires dust protection: Dust or foreign matter may interfere with infrared sensing.

5. How do I install Infrared Touch Screens?

Installing Infrared Touch Screens mainly includes the following steps:

Frame Fixing: Mount the IR frame on the edge of the monitor.

Sensor Alignment: Make sure the IR emitter and receiver are aligned to form a complete grating.

Connect Controller: Connect the touch screen control system via USB or other interface.

Software Configuration: Install drivers and perform calibration to ensure touch accuracy.

6. Technical Advantages of Infrared Touch Screens

Accurate touch detection: even stylus, gloves or other non-conductive objects can be accurately identified.

Multi-touch support: suitable for multi-user interaction scenarios, such as conference systems.

Durable and reliable: no physical wear and tear, suitable for high-frequency use.

Uncompromised image quality: no degradation of screen brightness and clarity.

Simple Maintenance: No need for frequent calibration, low daily maintenance costs.

Fast Response: Achieves <10ms touch response time.

Suitable for large displays: supports sizes of 32’ and above without complex structures.

Electromagnetic interference free: Suitable for medical, industrial and other special application scenarios.

7. Key features of Infrared Touch Screens

Reliable durability: no physical contact, long life.

High clarity and brightness: no extra diaphragm, does not affect the visual effect.

Support multiple input methods: finger, glove, stylus, etc. can be used.

Low maintenance cost: no need to replace the touch layer or calibrate the sensor.

Customisable size: can be adapted to different sizes of displays and interactive devices.

8. Infrared touch screens versus other touch technologies

| Characteristics | Infrared Touch Screen | Capacitive Touch Screen | Resistive Touch Screen |

| Touch Accuracy | high | high | Medium |

| Multi-touch | Support | Support | Not supported |

| Light Transmission | High | High | Low |

| Durability | High | Medium | Low |

| Maintenance Requirements | Low | Low | High |

| Applicable Size | 32″+ | 3″~32’ | 3″~20’ |

| Environmental Adaptability | Strong | General | General |

9. Maintenance and care tips for Infrared Touch Screens

Regular cleaning: Use a dry soft cloth to wipe the screen to avoid accumulation of dust affecting the sensing.

Avoid direct sunlight: Strong light may interfere with infrared sensing, and a light shielding design can be used.

Check the connection interface: Make sure the USB or controller interface is stable to avoid touch failure.

Stay away from high temperature and high humidity environment: avoid sensor failure due to environmental changes.

10. Industry Applications of Infrared Touch Screens

Digital signage: shopping malls, airports, self-service enquiry terminals.

Conference and education: intelligent whiteboard, large size interactive touch screen.

Industrial automation: clean room, intelligent control system.

Medical equipment: not subject to electromagnetic interference, suitable for medical touch interface.

Games and entertainment: large interactive touch wall, e-sports equipment.

11. Future Trends of Infrared Touch Screens

With the development of intelligent interaction technology, the application of infrared touch screen in the field of large-size touch control, intelligent conference, outdoor interactive equipment will continue to grow. In the future, faster response speed, more accurate multi-touch, and higher environmental adaptability will become the key direction of technological upgrading, while the combination with AI, 5G, and IoT will also broaden its application scenarios.

If you need reliable touch solutions, COMPT‘s industrial monitors and industrual panel computers are the ideal choice. We offer high-performance infrared touch technology that ensures fast response and superior displays for a variety of industrial needs.

FAQ for Infrared Touch Screens

1. What is an Infrared Touch Screen and how does it work?

An Infrared Touch Screen operates by emitting a grid of invisible infrared light beams across the screen surface. When a user touches the screen, their finger or another object interrupts these beams. The system detects this interruption and calculates the exact touch point based on the disrupted X and Y coordinates. This technology allows for touch detection without the need for direct contact with the screen surface.

2. What are the advantages of Infrared Touch Screens?

-

Infrared Touch Screens offer several benefits:

-

High Durability: They are resistant to physical damage since they don’t rely on a touch-sensitive overlay.

-

Excellent Image Clarity: The absence of additional layers ensures that display brightness and clarity remain unaffected.

-

Multi-Touch Support: Many infrared systems support multi-touch gestures, enhancing user interaction.

-

Versatility: They can detect input from various objects, including gloved fingers or styluses, making them suitable for diverse applications.

3. What are the disadvantages of Infrared Touch Screens?

Despite their advantages, Infrared Touch Screens have some limitations:

-

Sensitivity to Ambient Light: Strong infrared light sources, like direct sunlight, can interfere with touch detection.

-

Susceptibility to Dust and Dirt: Accumulation of contaminants on the screen’s edges can obstruct infrared beams, leading to touch inaccuracies.

-

Design Constraints: The need for a raised frame to house the infrared emitters and receivers can limit design options, preventing fully flat screen designs.

4. In which applications are Infrared Touch Screens commonly used?

-

Infrared Touch Screens are widely utilized in various sectors:

-

Interactive Kiosks and Self-Service Terminals: Providing intuitive user interfaces in public spaces.

-

Point-of-Sale (POS) Systems: Facilitating efficient transactions in retail environments.

-

Industrial and Medical Equipment: Offering reliable touch input in environments where users may wear gloves or where durability is paramount.

-

Educational Tools: Enhancing interactivity in classrooms through devices like interactive whiteboards.

5. How should Infrared Touch Screens be maintained?

To ensure optimal performance of your Infrared Touch Screen:

-

Regular Cleaning: Keep the screen and its edges free from dust and debris to prevent interference with the infrared beams.

-

Avoid Direct Sunlight: Position the screen away from strong infrared light sources to maintain touch accuracy.

-

Protect the Frame: Ensure the housing for the infrared emitters and receivers remains intact to prevent malfunctions.

-

Routine Inspections: Periodically check for any obstructions or damage that could affect the screen’s functionality.

Penny

Web Content Writer

4 years of experience

This article is edited by Penny, the website content writer of COMPT, who has 4 years working experience in the industrial PCs industry and often discusses with colleagues in R&D, marketing and production departments about the professional knowledge and application of industrial controllers, and has a deep understanding of the industry and products.

Please feel free to contact me to discuss more about industrial controllers. sales@gdcompt.com