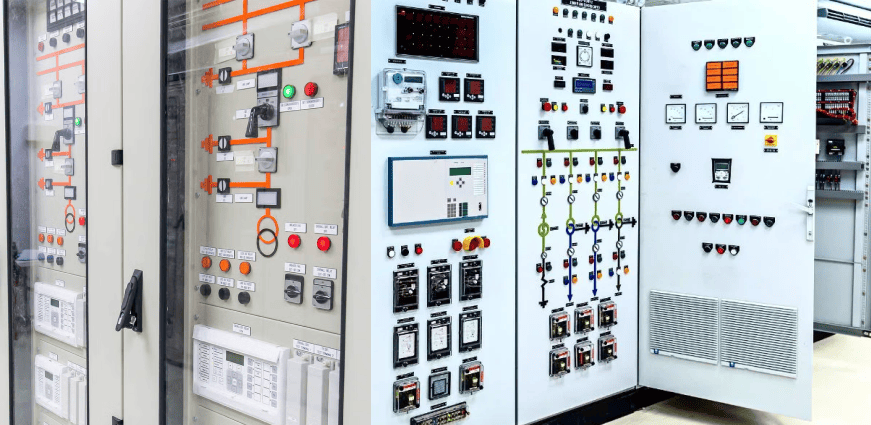

Overview of industrial control panels

Industrial control panels (ICPs) are key devices used to manage, monitor and control industrial electrical equipment and mechanical systems. It usually contains a number of electrical components, such as circuit breakers, relays, PLCs (programmable logic controllers), terminals, etc., through reasonable wiring and programme control, to achieve the automated operation and safety protection of the equipment.

In modern industrial scenarios, control panels are widely used in automated production lines, power transmission and distribution systems, chemical process control, building automation and many other fields. They not only enhance industrial efficiency, but also reduce operational risks through real-time monitoring and feedback functions.

A well-designed industrial control panels not only need to have good electrical functions, but also comply with the corresponding safety standards (such as UL 508A or IEC 61439) to ensure the stable operation of the equipment in a variety of complex environments. Therefore, it is not only the ‘brain’ of the equipment, but also one of the core infrastructures of an organisation to improve productivity and safety.

Types of Industrial Control Panels

COMPT classifies industrial control panels into various types according to their functions, structures and application environments. Proper selection of the type of control panel is critical to the stability and efficiency of system operation. The following are several common types of industrial control panels:

1. PLC control panel (Programmable Logic Controller Panel)

This is the most common type of industrial control panel, the core component is PLC, can be programmed to control complex automation tasks. It is suitable for all kinds of automated production lines and process control systems, and supports input/output module expansion with high flexibility and customisability.

2. Motor Control Centre (MCC)

Used to centrally control the start/stop and operation of multiple motors, commonly found in large manufacturing plants, wastewater treatment plants, and power stations, MCCs usually integrate contactors, thermal relays, and soft starters, which helps to improve the centralisation of motor control and maintenance efficiency.

3. Distributed Control Panels (DCS Panels)

This type of control panel is suitable for large process industries such as chemical, refining etc. Through multiple control nodes for remote collaborative control, real-time response and optimal scheduling of complex systems.

4. Power Distribution Panels (Power Distribution Panels)

Mainly used for power distribution and protection system, providing stable and reliable power supply for control equipment. These panels have built-in circuit breakers, disconnect switches and other components, and are commonly used in main control systems or distribution stations.

5. Custom Control Panels

For special working conditions, such as outdoor, high temperature, explosion-proof and other environments, users can choose custom control panels. They usually adopt high level protection housing (e.g. IP65/IP66), and combined with special cooling system or redundant control structure.

Different types of industrial control panels have their own focus in terms of structure, functionality and application, and companies should choose according to their automation needs, control complexity and budget.

Key Components of an Industrial Control Panel

The performance and reliability of an industrial control panel depends greatly on the configuration and quality of the key components within it. The following are the main core components that make up a control panel:

1. Programmable Logic Controller (PLC)

PLC is the ‘brain’ of the industrial control panel, which is used to receive input signals, execute control logic and output control commands. It supports flexible programming, can handle complex automation processes, is an indispensable core equipment for modern industrial control systems.

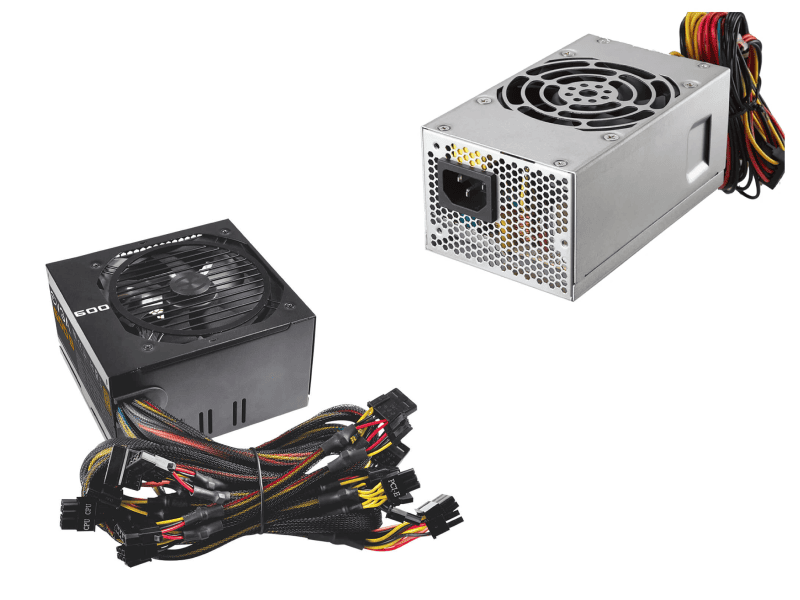

2. Power Supply Module (Power Supply)

The power supply module converts AC power into stable DC power to provide stable power security for the entire control system. Reliable power supply is to ensure that the system continues to run on a stable basis, especially in the frequent voltage fluctuations in the industrial environment is more important.

3. Contactors and Relays

These electrical components are responsible for switching circuits and controlling the start and stop of high-power equipment. Contactors are used for remote control, while relays are often used for logic control and protection circuits.

4. Circuit Breakers

Circuit breakers are used to prevent overloading or short-circuiting of the current. In case of an electrical fault, it will automatically break the circuit to protect the equipment and the operator.

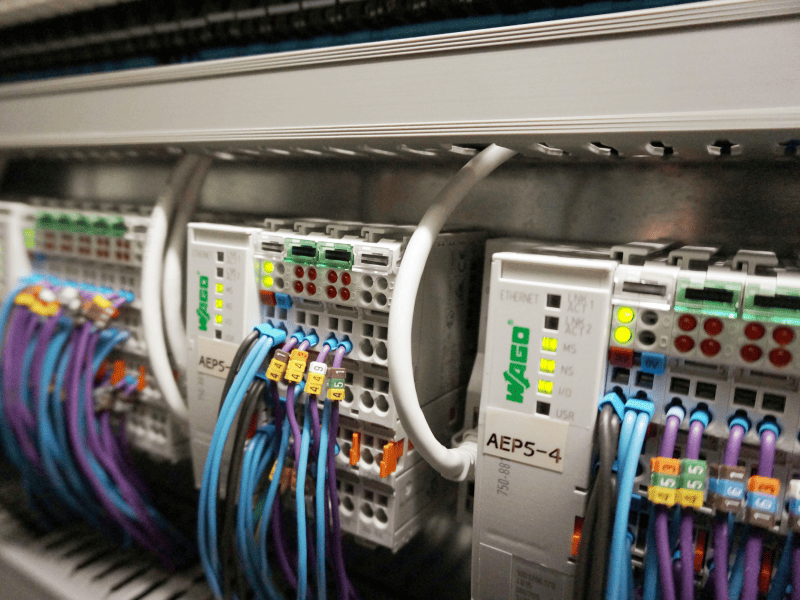

5. Terminal Blocks & Connectors

Terminal Blocks & Connectors are used to connect the components and external devices to ensure the stable transmission of signals and power. Good wiring management can greatly enhance the maintainability of the control panel.

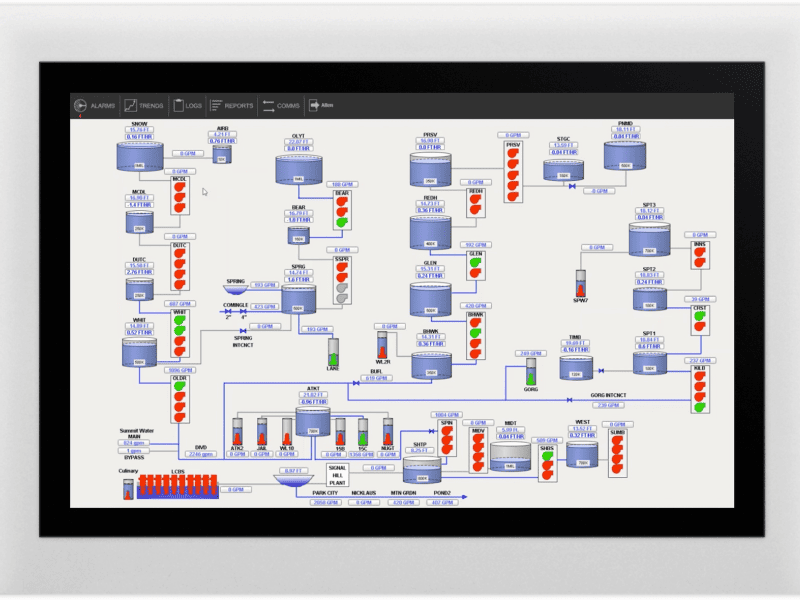

6. Human-Machine Interface (HMI, Human-Machine Interface)

HMI devices such as touch screens, display panels, etc., to provide a visual operating interface to facilitate operator status monitoring, parameter setting and troubleshooting.

These components work together to enable industrial control panels to perform precise, efficient and safe automation tasks. During the design and selection process, choosing key components with reliable brands and stable performance is critical to the long-term operation of the control system.

Parameters to consider when designing industrial control panels

The design of industrial control panels is not just a stack of components, but a systematic project. Reasonable design is directly related to the safety, reliability and maintainability of the control system. The following are the key parameters that must be considered during the design process:

1. Installation environment

The environment in which the control panel is used will affect its enclosure material, protection level and heat dissipation scheme.

For example:

High temperature, high humidity or dusty environments require IP65 or higher protection;

Outdoor applications may require rain and UV protection;

Explosion-proof areas require explosion-proof certified enclosures and components.

2. Load capacity and electrical capacity

According to the total power of the field equipment, start-up mode and operating characteristics of the reasonable selection of power supply specifications, cable cross-section and overload protection components, to avoid faults or fires caused by overloaded current.

3. Heat management and ventilation system

Electrical components generate a lot of heat during operation, and poor heat dissipation will lead to performance degradation or shortened life. Common solutions include the installation of cooling fans, ventilation shutters, heat exchangers and even air conditioning systems.

4. Modularity and Space Layout

The internal structure should reserve enough space for operation and expansion, and the modular design is convenient for future maintenance, replacement and system upgrading. At the same time, reasonable wiring helps to reduce interference and improve system stability.

5. Electromagnetic interference (EMI) and grounding design

Control panel design should follow good grounding rules to avoid signal interference and leakage problems. Important signal lines should use shielded cables, and away from strong power lines.

6. Human Machine Interaction and Maintenance Convenience

HMI layout location, wiring and the accessibility of the control elements need to give full consideration to the operator’s experience and safety, to enhance the efficiency of the site response.

Excellent industrial control panel design is a balance of performance, safety and efficiency, only in the early stages of full consideration of the design parameters, in order to achieve stable and efficient operation in later use.

Regulatory Standards for Industrial Control Panels

Industrial control panels are concerned with electrical safety, system stability and operational regulations and must comply with the relevant international and regional standards. These standards not only guarantee the safety of the equipment itself, but also ensure that it can legally enter its target market.

1. UL 508A (American Standard)

UL 508A is the most widely used standard for industrial control panels in the U.S. It was developed by Underwriters Laboratories (UL) and applies to electrical control panels up to 1000V. The main contents include:

Selection of electrical protection components

Conductors and wiring rules

Enclosure protection level requirements

Mandatory marking and nameplate specifications

UL 508A certified control panels are more likely to pass factory or third-party safety audits and meet U.S. market access requirements.

2. IEC 61439 (International Standard)

IEC 61439 is the International Electrotechnical Commission’s standard for low-voltage distribution control cabinets, applicable to industrial equipment worldwide. The standard focuses more on performance verification and structural testing, emphasising:

Mechanical strength of panels

Temperature rise limit tests

Electrical clearances and creepage distances

Protection classes and safety distances

In Europe, Middle East and Asia, IEC standard is an important reference for control panel design and certification.

3. CE certification (EU)

All industrial control panels entering the EU market must obtain the CE marking, which means that the product meets the requirements of the Low Voltage Directive (LVD) and the Electromagnetic Compatibility Directive (EMC). Manufacturers are required to submit:

Declaration of Conformity (DoC)

Technical documentation and test reports

Risk Assessment and Operating Instructions

4. CSA Standard (Canada)

Similar to UL standards, CSA (Canadian Standards Association) has developed safety specifications for control panels. The Canadian market especially values the CSA certification label.

5. Chinese Standard (GB/T Series)

In the Chinese market, industrial control panels are usually required to comply with national standards such as GB/T 7251 (Low-voltage complete sets of switchgear and controlgear) and to pass the national compulsory product certification (CCC certification).

Regulatory requirements for industrial control panels

In addition to compliance with standards, industrial control panels have a number of specific regulatory requirements that need to be met in practice.

1. Compliance assessment at the design stage

In the early stages of product development, engineers must design structural and electrical solutions according to the standards of the target market (e.g. UL, IEC, CE), including:

Whether the component selection is certified

Whether loop protection settings meet current and voltage requirements

Wiring diagrams, electrical drawings, whether the symbols of the standard, clear identification

2. Document preparation and archiving of technical information

Regulatory authorities or third-party auditing organisations usually require the following documents at the acceptance stage:

Control panel design drawings (wiring diagrams, wiring diagrams, layout diagrams)

Component list (BOM)

Risk assessment documents and safety instructions

Structural and insulation test reports

This information needs to be kept for a long time, so that it is easy to trace back and technical support at a later stage.

3. Function test and insulation test before delivery

The control panel has to go through a number of tests before leaving the factory, including:

Electrical insulation and voltage testing

Ground continuity test

Functional simulation test

Safety fault simulation test (e.g. power failure protection, overload simulation)

After passing the test, the test record and passing mark should be attached.

4. Post-installation site audit

After installation at industrial sites, certain industries such as petrochemical, electric power, construction, etc. also need to pass:

On-site wiring check

Integral control system linkage test

Safety emergency stop and emergency power-off system test

Marking, nameplate and warning label checks

Audits are conducted by in-house engineering, safety officers or government third-party organisations. Failure to meet requirements may result in project delays or rejection.

5. Annual Inspection and Re-certification (some regions)

Some high-risk industries or specific countries, such as the U.S. or Germany, require periodic inspection and recertification of control systems to prevent accidents caused by deterioration and failure.

The regulatory requirements for industrial control panels run through the entire product life cycle, and companies should not only consider compliance in the design and production phase, but also pay continuous attention to changes and updates in regulatory standards during the use and maintenance phase.

Trends in industrial control panels

With the rapid development of Industry 4.0 smart manufacturing and the Internet of Things (IoT), industrial control panels are also undergoing a deep transformation. Traditional control equipment is evolving in the direction of digitalisation, modularisation and intelligence, bringing more possibilities for industrial automation.

1. Intelligent control system

Modern industrial control panels are increasingly integrated with sensors, data acquisition modules and intelligent algorithms to achieve real-time monitoring of the state of the equipment and predictive maintenance, significantly improving operation and maintenance efficiency and reducing the risk of failure.

2. IoT Remote Control and Cloud Platform Docking

Through networking capabilities, the control panel can be remotely monitored and operated, and even integrated with ERP, MES and other systems to realise a closed loop of data from the workshop to management. Cloud-based analytics also provide manufacturing companies with more accurate production optimisation recommendations.

3. Modular and integrated design

The new generation of control panels pursues a high degree of integration, integrating control, display, communication, and data processing on the same platform as far as possible, simplifying wiring, reducing space occupation, and improving system stability.

4. Environmental protection and energy saving design

Energy saving has become an important evaluation index for industrial systems, and control panels are gradually adopting low-power components, high-efficiency heat dissipation solutions, and intelligent energy consumption monitoring systems to help companies achieve the goal of green factories.

In this context, choosing a high-performance Industrial Panel PC (Industrial Panel PC) has become the key to upgrading the control system of enterprises.

⭐ Recommended Brand: COMPT Industrial Panel PC

COMPT Industrial Panel PC is designed for harsh industrial environments with the following advantages:

Ruggedness: supports dustproof and waterproof (IP65/IP66), wide temperature operation, suitable for outdoor or harsh workshop environments

Multiple size options: from 7 inches to 21.5 inches to meet different control needs.

High-performance platform: equipped with Intel i5/i7 processor, built-in SSD, high-speed memory.

Rich interfaces: support serial port, USB, LAN, CAN, etc., convenient to interface with PLC, sensors, industrial gateway.

Strong compatibility: Support Windows/Linux system, perfect integration with SCADA, MES and other industrial software.

https://www.gdcompt.com/products/

Penny

Web Content Writer

4 years of experience

This article is edited by Penny, the website content writer of COMPT, who has 4 years working experience in the industrial PCs industry and often discusses with colleagues in R&D, marketing and production departments about the professional knowledge and application of industrial controllers, and has a deep understanding of the industry and products.

Please feel free to contact me to discuss more about industrial controllers. sales@gdcompt.com