When you need to use a computer in an industrial environment to handle specific tasks, configuring a reliable and functional industrial PC is a necessity. Configure An Industrial Pc (IPC) is a process that takes into account the specific needs of the device in terms of application scenarios, operating environment, hardware specifications, operating system, and many other specific requirements.

(Image from the web, If there is any infringement, please contact zhaopei@gdcompt.com)

1. Determine the needs

First of all, to clarify the use of industrial PC scenarios and specific needs, including:

Use of the environment: whether the need for dust-proof, waterproof, shockproof, anti-electromagnetic interference.

Performance requirements: need to deal with the task of data acquisition, monitoring, control or data analysis.

Interface requirements: the type and number of input and output interfaces required, such as USB, serial, Ethernet, etc.

2. Select the appropriate hardware

2.1 Processor (CPU)

Choose the right CPU, considering performance, heat dissipation and power consumption. Common options are:

Intel Core series: For high performance needs.

Intel Atom series: Suitable for low-power, long-running requirements.

ARM architecture processor: Suitable for embedded systems, low-power applications.

2.2 Memory (RAM)

Select the appropriate memory capacity and type according to the application requirements. General industrial PC memory ranges from 4GB to 32GB, high-performance applications may require a larger memory, of course, different capacity, different prices, but also take into account the budget.

2.3 Storage Device

Select an appropriate hard drive or solid state drive (SSD), considering capacity, performance and durability.

Solid State Drives (SSD): Fast read speeds, good shock resistance, suitable for most industrial applications.

Mechanical hard discs (HDD): suitable for high-capacity storage needs.

2.4 Display and Graphics

If graphics processing power is required, choose an industrial PC with a discrete graphics card or a processor with powerful integrated graphics processing power.

2.5 Input/output devices

Select the appropriate network interface according to specific needs:

Select appropriate input devices (e.g. keyboard, mouse or touch screen) and output devices (e.g. monitor).

Ethernet: single or dual network ports.

Serial port: RS-232, RS-485, etc.

Wireless network: Wi-Fi, Bluetooth.

Expansion slots and interfaces: Make sure the PC has enough expansion slots and interfaces to meet the application requirements.

3. Installation of operating system and software

Choose a suitable operating system, such as Windows, Linux, or a dedicated real-time operating system (RTOS), and install the required application software and drivers. Install the necessary drivers and updates to ensure that the hardware is working properly.

4. Determine the enclosure for the industrial PC

Select the right type of enclosure by considering the following factors:

Material: metal and plastic housings are common.

Size: Choose the right size based on the installation space.

Protection level: IP rating (e.g. IP65, IP67) determines the dust and water resistance of the device.

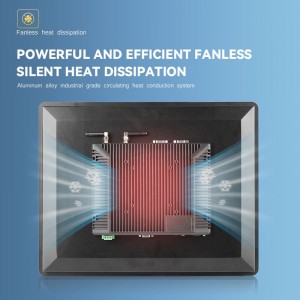

5. Select power supply and thermal management:

Ensure that the PC has a stable power supply. Select an AC or DC power supply according to the needs of the device, ensure that the power supply has sufficient power output, and consider whether uninterruptible power supply (UPS) support is required in case of power interruption.

Configure the cooling system to ensure that the PC remains stable during extended operation and in hot environments.

6. Network configuration:

Configure network connections, including wired and wireless networks.

Set network parameters such as IP address, subnet mask, gateway, and DNS servers.

Configure remote access and security settings, if required.

7. Testing and validation

After the configuration is completed, conduct rigorous tests, including performance tests, environmental adaptability tests and long-time running tests, to ensure the reliability and stability of the industrial PC in the actual application environment.

8. Maintenance and performance optimisation

Regular maintenance and updates are performed to ensure system security and the latest version of software to address potential security threats and performance issues.

Adjust operating system and software performance settings according to application requirements.

Consider using technologies such as virtual memory and hard disc caching to improve performance.

Monitor the performance and resource usage of the PC to identify problems and make adjustments in a timely manner.

The above are the basic steps for configuring an industrial PC. Specific configurations may vary depending on application scenarios and requirements. During the configuration process, reliability, stability and adaptability are always the main considerations. Before proceeding with configuration, please ensure that you understand the application requirements and hardware specifications, and follow relevant best practices and standards.

Configure Your Panel PC in Just a Few Clicks

Penny

Web Content Writer

4 years of experience

This article is edited by Penny, the website content writer of COMPT, who has 4 years working experience in the industrial PCs industry and often discusses with colleagues in R&D, marketing and production departments about the professional knowledge and application of industrial controllers, and has a deep understanding of the industry and products.

Please feel free to contact me to discuss more about industrial controllers. sales@gdcompt.com