What is an industrial monitor?

An industrial monitor is a professional-grade display device designed for use in harsh or unique environments. Compared with ordinary consumer-grade displays, industrial displays have higher requirements in terms of structure, performance and durability, and are able to operate continuously and stably in complex environments such as high temperature, low temperature, humidity, dust, vibration, and electromagnetic interference.

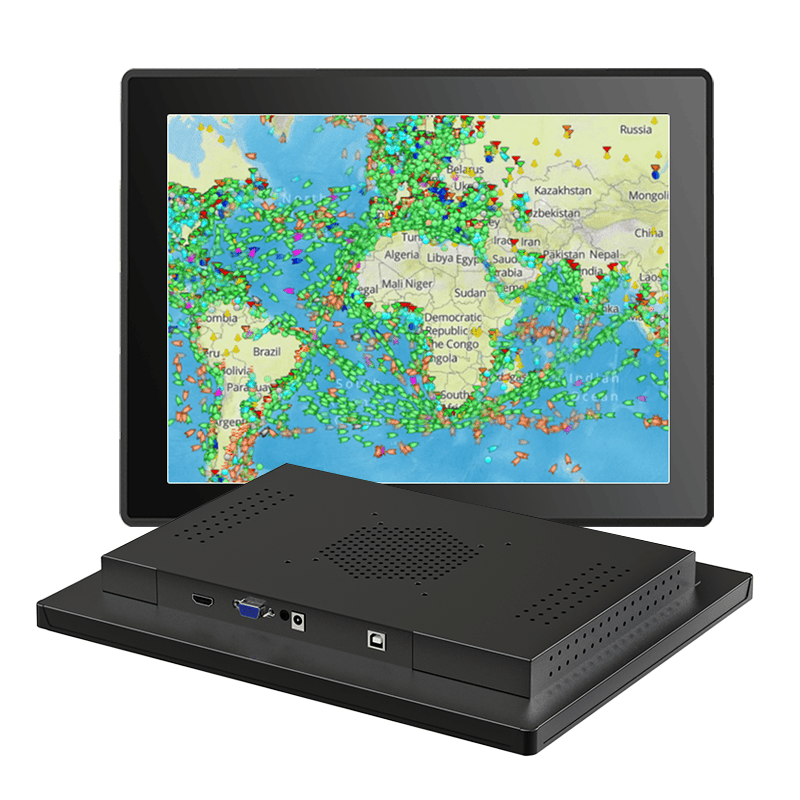

They are commonly used in factory automation, intelligent equipment, marine vessels, traffic control, medical, energy, outdoor kiosks, etc. They support long-time 24/7 operation and have a variety of installation methods (such as panel embedded, wall-mounted, rack-mounted, etc.) and a variety of interface options (such as VGA, HDMI, DVI, DisplayPort, etc.), and can also be equipped with touch-screen functionality.

Why customise the brightness of your monitor?

When industrial monitors are in high-light areas, outdoors, or under direct sunlight, normal brightness screens tend to whiten, reflect or even become unreadable. The display looks hazy, dark, and even has a halo on the screen. While high brightness displays (e.g., 1000~3000 nits) are clearly visible and can effectively improve readability, which is widely used in traffic, energy, maritime, agriculture, and other scenarios.

In addition, customised brightness also balances energy consumption and heat dissipation, extends equipment life, and combines technologies such as auto-dimming, optical lamination, and anti-glare treatment to enhance visual effects and operational safety. Choosing the right brightness not only enhances the user experience but is also an important factor in ensuring the stable operation of industrial applications.

Standard Monitors vs High Brightness Monitors

Standard displays typically have a brightness of 200-600 nits and are suitable for indoor or light-controlled environments. However, in bright light or direct sunlight scenarios, such as outdoor kiosks, traffic control, marine equipment, etc., these screens are prone to blurred content and severe reflections, making them impossible to read properly.

In contrast, high-brightness industrial displays can reach 1000, 2000, or even 3000 nits, keeping the picture clear and colours true even under bright light. Often equipped with anti-glare treatment, automatic brightness adjustment, and optical lamination technology, they are designed for harsh lighting environments and are widely used in industrial and outdoor scenarios where high brightness is required.

Benefits of Customised High Brightness

Customising the brightness of industrial displays not only ensures legibility in direct sunlight and reduces glare, but also improves the efficiency of information recognition and operational responsiveness, which is particularly important in outdoor or high-light environments.

At the same time, high brightness customisation helps to optimise energy consumption and heat dissipation management, extends equipment life, and can be combined with advanced technologies such as optical lamination and automatic brightness adjustment to achieve better visual performance and system stability.

Technical realisation of brightness adjustment

Brightness adjustment of industrial displays is mainly achieved by high-efficiency LED backlighting combined with PWM (Pulse Width Modulation) or DC dimming technology. The latest dimming technology supports dynamic LED brightness adjustment, automatically optimising the output according to the ambient light, taking into account both readability and energy efficiency. Meanwhile, the optical lamination process is adopted to closely fit the touch glass to the display surface, effectively reducing reflections and preventing water vapour and fog from interfering.

Does high brightness affect power consumption and lifetime?

High brightness does increase power consumption and heat, so it requires reasonable thermal design and energy efficiency optimisation.COMPT adopts energy-saving LED backlight and intelligent dimming solution to effectively control power consumption and extend the life of the display. By matching the brightness level with the actual running time customisation, it achieves a win-win situation in terms of performance and durability.

How to assess the appropriate brightness range?

To assess the brightness of the monitor, the ambient light intensity of the application scene needs to be considered. For example:

Indoor low light environment: 500 nits

Bright indoor or covered natural light: 1000 nits

Outdoor direct sunlight scene: 1500-3000 nits

It is recommended to combine the actual case test or communicate with professional manufacturers for on-site evaluation.

Monitor&display User Case Sharing

A manufacturing customer deployed COMPT’s 1000nits industrial displays in a high-brightness factory, mounting them via VESA on high-level equipment and keeping the image clearly visible even with strong overhead and skylight natural light. The combination of optical lamination and anti-reflective glass effectively improves operator response efficiency.

COMPT Provides Professional Brightness Customisation Service

COMPT supports 300~3000 nits brightness customisation with anti-reflective glass, auto-dimming, optical lamination and other technologies to meet the needs of high-standard applications such as medical, military, transportation, marine and outdoor equipments, helping you to easily meet the challenges of various lighting environments.

Brightness customisation has become a key indicator that cannot be ignored in industrial displays. Whether it is to improve sunlight readability or optimise equipment energy efficiency, COMPT can provide you with professional and reliable solutions for industrial display brightness customisation.

Penny

Web Content Writer

4 years of experience

This article is edited by Penny, the website content writer of COMPT, who has 4 years working experience in the industrial PCs industry and often discusses with colleagues in R&D, marketing and production departments about the professional knowledge and application of industrial controllers, and has a deep understanding of the industry and products.

Please feel free to contact me to discuss more about industrial controllers. sales@gdcompt.com