With the continuous advancement of Industry 4.0 and intelligence, the industry applications of commercial all in one pc and industrial all in one computers are accelerating the differentiation and presenting a trend of deep integration.

The commercial all in one pc field focuses on office, education, and home scenarios, focuses on lightweight design and intelligent interaction, and improves daily efficiency through cloud service integration (e.g., remote printing, multi-device collaboration);

The industrial all in one computer field relies on AI algorithms, edge computing and IoT technologies to realize real-time data processing and equipment linkage control in intelligent manufacturing, smart city, medical equipment and energy monitoring scenarios, with its customized requirements (e.g., wide-temperature operation, anti-electromagnetic interference) and modular scalability becoming its core competitiveness.

COMPT as a 10 + years of industrial computer manufacturers, has been asked many times about the difference between industrial computer all-in-one and commercial computer all-in-one, today to expand and talk to you in detail.

all in one computer uses and functions

Industrial all in one pc is designed for industrial scenarios, such as industrial automation, intelligent manufacturing, production line control, equipment monitoring, data acquisition and intelligent terminal interaction, supporting industrial protocols (e.g. Modbus, Profinet) and complex tasks (e.g. edge computing, machine vision). It has rich expansion interfaces to connect PLCs, sensors and other devices to meet automation needs. Industrial computers are also characterized by real-time, reliability and security to meet the requirements of industrial automation for precise control, efficient production and data acquisition.

Commercial all in one computer is oriented to office, education and home entertainment and other consumer market areas, in the office applications, Internet browsing, multimedia entertainment and social networking to meet the daily needs of individuals and enterprises, the interface to the general-purpose-based (such as USB, HDMI), the expansion of the weaker.

all in one pc design

Industrial all in one pc adopts full metal shell (aluminum-magnesium alloy/stainless steel), protection level up to IP65/IP67, dustproof and waterproof, and equipped with high-brightness screen (more than 500cd/m²), support glove touch (resistive or infrared screen). Typically industrial all in one computer is divided into four categories, shelf-type industrial computers, industrial touch all-in-one computer, fanless industrial control machine, three anti-class special computers.

Commercial models focus on aesthetic appearance, mostly with plastic frames, lower screen brightness (250-300cd/m²), only support capacitive screen touch, and no professional protection.

Differences in system security

Industrial models integrate physical locking, BIOS-level encryption chip (TPM 2.0) and national secret algorithms (SM2/SM4), support redundant storage of data (RAID), and defend against virus attacks with customized security kernel (e.g. Kirin OS).

Touch (or non-touch) monitor and computing as one of the industrial computer, generally based on the size of 7 inches, 8 inches, 10 inches, 12 inches, 15 inches, 17 inches, 19 inches, 21 inches, 23.6 inches, 32 inches, etc.; according to the surface of the touch control can be divided into sonic touch-screen, infrared touch-screen, resistive touch-screen, capacitive touch-screen and other forms of the commonly used form of touch is a resistive touch-screen and multi-touch capacitive touch-screen. Touch screen, resistance touch screen is characterized by stability, will not be used in the environment of electromagnetic radiation interference, capacitive touch screen is characterized by a good user experience, the actual role of the need to make different choices for different applications;

Fanless industrial control machine (industrial pc), generally refers to the industrial environment in order to adapt to the design of the heat dissipation of industrial computers, fanless design can be avoided due to the failure of the fan caused by overheating equipment and crash;

rugged tablet computer, respectively, rugged tablet tablet tablet PC, rugged tablet laptop, rugged fanless industrial computer, rugged tablet products require products waterproof, dustproof, anti-vibration, some also need to anti-shock, anti-salt spray, anti-mold and so on, and even required to work in the high-altitude low-pressure, which requires the structural design of these products. Requirements for such products, the structure of the tight design, there can be no gaps to prevent water, sand and dust from entering the equipment inside, the general protection level expressed in IPXX.

Commercial models rely on software encryption (e.g. BitLocker), no hardware-level protection, frequent system updates may lead to compatibility issues.

all in one pc usage environment comparison

Industrial All-in-One:

– Extended Temperature Range: With the Extended Temperature Range design, the industrial model can work stably under storage temperature from -40°C to 85°C and operation temperature from -20°C to 70°C (compliant with MIL-STD-810G military standard).

- Fanless cooling technology: Passive cooling (e.g. aluminum fins + heat pipes) to avoid the risk of downtime due to fan failure, suitable for hot workshops or outdoor sun exposure scenarios.

Commercial all-in-one machine:

- Strong temperature control dependence: only supports 5°C to 38°C ambient temperature, beyond the range of overheating protection or low-temperature startup failure, can not be used in cold storage, steel mills and other scenarios.

Industry case:

- An oil drilling platform uses an industrial all-in-one machine (wide temperature -30°C to 60°C) to monitor the status of the equipment in real time; while commercial models cause deformation of the motherboard due to high temperature in the same environment.

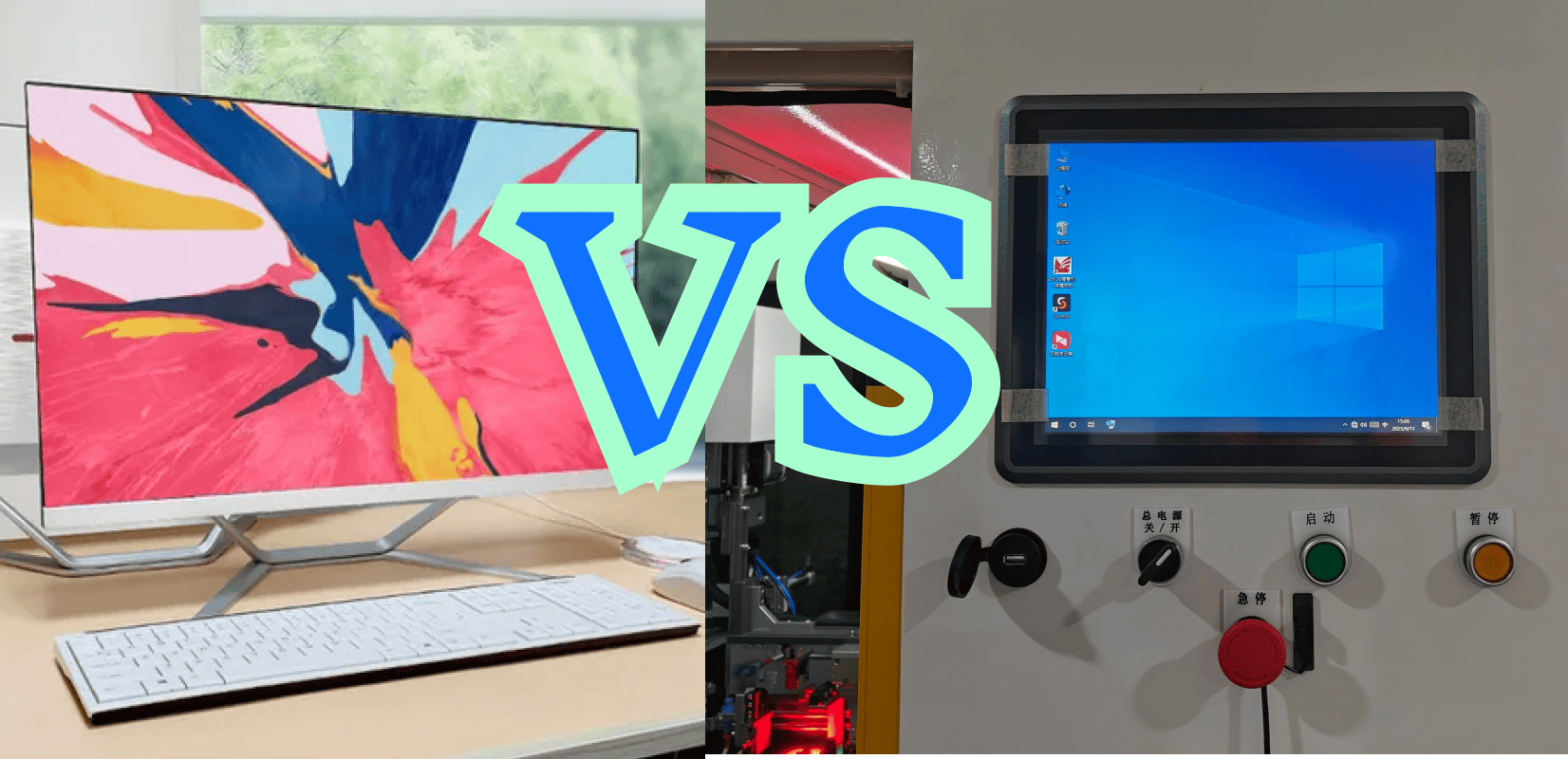

Commercial VS Industrial All-in-One: Design Differences

Construction Durability

Commercial: plastic/aluminum alloy shell, thin and light design.

Industrial: Metal body, IP65 dustproof and waterproof, shock and vibration resistant.

Heat Dissipation

Commercial: fan cooling, easy to accumulate dust.

Industrial: Fanless design, adaptable to high temperature and dusty environment.

Screen and Touch Control

Commercial: Ordinary LCD/LED screen, limited touch support.

Industrial: High brightness anti-glare PCAP screen, glove touch, scratch-resistant and durable.

Environmental Adaptability

Commercial: 0°C~35°C indoor environment only.

Industrial: -10°C~60°C wide temperature operation, anti-electromagnetic interference.

Extended Interface

Commercial: USB, HDMI and other basic interfaces only.

Industrial: RS232, RS485, GPIO, LAN, compatible with automation system.

Commercial VS Industrial All-in-One: Comparison of Test Conditions

✅Environmental adaptability

Industrial: High and low temperature (-40°C~70°C), humidity, vibration shock test to adapt to harsh environment.

Commercial: only for room temperature office environment (0°C~35°C).

✅Protection Rating

Industrial: IP65/IP66 Dust and water resistant, suitable for outdoor and factory.

Commercial: No special protection, suitable for indoor only.

✅ Stability

Industrial: 7×24 hours high load operation test to ensure long-term stability.

Commercial: Tested for daily office needs, not suitable for continuous high intensity work.

✅ Durability

Industrial: Anti-drop, anti-electromagnetic interference (EMI/EMC), greater durability.

Commercial: tested for basic safety, lower immunity to interference.

Conclusion: Industrial MFPs are more durable and stable, suitable for harsh environments such as factories and logistics; commercial MFPs are more suitable for general office and retail scenarios.

Lifespan & Reliability: Business All-in-One vs Industrial All-in-One

Business MFPs are typically designed for use in office or home environments, with lower usage requirements, a typical lifespan of 3-5 years, and less adaptability to environmental conditions. They are relatively unreliable and rely heavily on regular indoor use.

Industrial All-in-Ones are designed for harsh environments and have a longer lifespan, typically 5-10 years or more. They are able to operate stably in extreme temperatures (-40℃ to +70℃), high humidity, high dust, vibration and other environments, with higher dust and waterproof rating and anti-vibration ability, and their reliability is much better than that of commercial All-in-One PCs.

Summary: Industrial MFPs are far more reliable than commercial MFPs in terms of service life and reliability, and are especially suitable for long-time operation in harsh environments.

Operating System Differences: Commercial All-In-One PCs vs Industrial All-In-One PCs

Commercial All In One PCs (CAPS) Operating System: Usually pre-installed with Windows 10/11 or macOS, suitable for daily office, entertainment and light applications. Suitable for Office software, web browsing, video playback and other common applications.

Industrial All In One PCs (IAPCs) OS: Mostly support Windows Embedded, Linux or Android system, designed for industrial control, automation, IoT and other professional needs. The system supports real-time operation, application-specific customization, and usually requires higher stability and compatibility to ensure long-term operation.

Summary: Commercial MFPs favor general-purpose operating systems for office and entertainment, while industrial MFPs use more specialized and customized operating systems to meet the specific needs and reliability requirements of industrial environments.

Selection advice: the difference between commercial all-in-one machine and industrial all-in-one machine

1. Use of the environment

Business all-in-one machine: suitable for office, retail and other environments, the conditions are more stable.

Industrial MFP: Adapt to high temperature, low temperature, humidity, dust and other harsh industrial environments.

2. Performance Requirements

Business All-in-One: Suitable for light office tasks with medium configuration.

Industrial All-in-One PCs: support high load applications and require 24/7 stable operation.

3. Customization Requirements

Business All-in-One: No customization needs, standardized products are sufficient.

Industrial MFPs: support customized configurations to meet the needs of industrial control systems.

4. Durability and Life Cycle

Commercial All-in-One: shorter life cycle, suitable for 2-3 years cycle.

Industrial All-in-One: more durable design, long service life, suitable for long-term use.

5. Cost

Business MFPs: lower cost, suitable for daily office applications.

Industrial MFP: Higher cost, but offers high reliability, suitable for long term investment.

In summary, choosing the right All-in-One PC is crucial, especially in industrial environments where the durability, stability and customization needs of the device often determine its long-term performance. For application scenarios that require harsh working conditions and long hours of high load operation, choosing an industrial all-in-one PC is undoubtedly a smarter decision.

As a leading brand in the industry, COMPT provides industrial all-in-one products with excellent anti-interference, long life and high performance to meet the needs of various complex industrial applications. Whether it’s smart manufacturing, automation control, intelligent transportation, or medical devices, COMPT Industrial All-in-One PCs can provide customized solutions to help your business achieve efficient operations.

Penny

Web Content Writer

4 years of experience

This article is edited by Penny, the website content writer of COMPT, who has 4 years working experience in the industrial PCs industry and often discusses with colleagues in R&D, marketing and production departments about the professional knowledge and application of industrial controllers, and has a deep understanding of the industry and products.

Please feel free to contact me to discuss more about industrial controllers. sales@gdcompt.com