Touch screens are everywhere, but did you know that they come in several different sizes and use very different mechanics? Most commercial touch screens can be divided into two categories: capacitive and resistive.

Choosing between Capacitive Vs. Resistive touch screens are a serious consideration when you’re designing a commercial product. Putting the wrong screen will be financially draining, and reduce the marketability of the design. So, in this article, I’ll explain the mechanics behind these touch screens so you can make a more informed decision.

Basics of Touch Screen

Touch screens work by registering human input through touch to produce an output. The difference between touch screens lies in how they complete the registering process.

Both the capacitive and resistive touch screens register touch through electrical signals. Other touch screens use infrared and even ultrasound to detect touch. For most commercial machines the resistive and capacitive touch screens are the standard.

For one, both resistive and capacitive touch screens are significantly cheaper than infrared and acoustic touch screens.

Capacitive Touch Screen VS. Resistive Touch Screen Explained

Capacitive touchscreens and resistive touch screens have very similar mechanical builds, but they differ in how the screens interact. Here’s a detailed breakdown:

1. Resistive Touch Screens

Resistive touch screens use two separate panels as their screen. The top and bottom panels are made with transparent compositive materials coated with ITO or Indium Tin Oxide. It’s also a clear coating. The ITO layer gives the composite screens a uniform resistance value over the surface.

The top layer is usually made of PET film or polycarbonate plastic, which are somewhat flexible. The top layer needs flexibility because it needs to cave in when you press on it to make contact with the rigid bottom layer. The bottom layer is usually made of glass.

Between these two layers are the spacer dots. These are tiny spacer dots. These dots are bound to the rigid bottom layer. When you press on the flexible top layer, the layer comes into contact with these dots to register the touch. There are electrodes around the border of the screens that obtain the X and Y Axis data on the screen to triangulate the precise location of the touch.

Resistive touch screens can be divided into 4 categories:

Digital matrix resistive

Digital matrix resistive is the oldest version of resistive touch screens. This touch screen uses crisscrossing stripes of electrodes between the top and bottom sheets to detect touch points. You wouldn’t see this technology anymore, as most have already moved on to analog ones.

Analog 4-wire resistive

Analog 4-wire resistive has the same structure as I explained above, it just separates the directional electrodes into the two panels. One panel carries the electrodes for sensing the vertical touch points, and the other carries the ones for horizontal ones.

Analog 5-wire resistive

In the 5-wire resistive touch screen, the bottom layer carries electrodes for sensing both vertical and horizontal directions. The top sheet only handles the tactile touch.

Analog 8-wire resistive

8-wire resistive touch works exactly the same way as the 4-wire ones except they have an extra 4 sets of wires to add more sensors. It’s basically an advanced version of a 4-wire resistive that is more durable and boasts higher accuracy.

2. Capacitive Touch Screens

Capacitive touch screens do not have moving mechanical parts like resistive touch screens. It usually comprises two sheets of rigid surfaces, usually various types of reinforced glass. There are two types of capacitive touch screens: the surface capacitive and the projected capacitive. Both work quite differently from one another so they require their own explanations.

Surface Capacitive

The surface capacitive touch screens have two panels with a rigid glass at the bottom and a glass coating at the coating at the top. In between these two panels is the transparent conductive coating.

There are four electrodes placed at the 4 corners of the screen, which creates an even field of electrical current. When you place your hand on the surface, it disrupts the even current, and the sensors detect the point of touch.

Projected Capacitive

Projected Capacitive touch screens have a very similar structure to the matrix touch screen. It’s a 5-layer structure with a top and bottom layer of reinforced glass. There’s a layer of y electrodes below the top glass layer and a layer of X electrodes above the bottom glass layer.

The X and y electrode layers are separated by a layer of adhesive. When you touch the glass surface of the projected capacitive screen, the X and Y electrode layers will sense the electrical current from your hand and pinpoint the touch location.

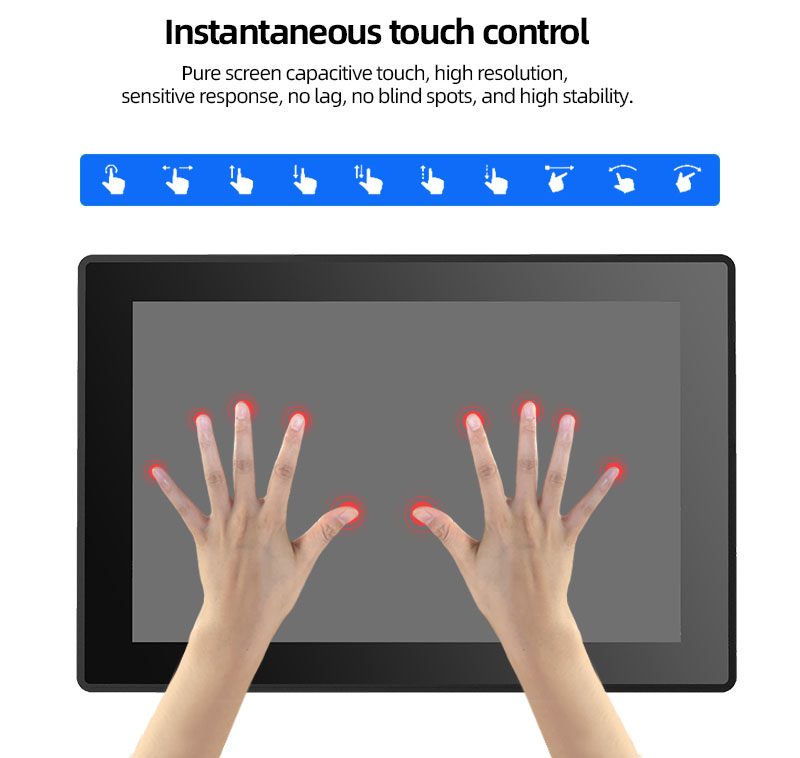

Projected Capacitive Multitouch Technology

A “projected capacitive multitouch” touchscreen is a type of screen that detects and responds to human touches by using the electrical properties of the human body. Unlike resistive screens that require physical pressure to function, capacitive screens work by detecting changes in the electrical capacitance (also known as capacitance) at the surface of the screen when it is touched by a finger or a conductive object.

Capacitive touchscreens are made from a layer of conductive glass or a transparent film with electrical conductivity. This layer is often made from indium tin oxide (ITO) or other similar conductive materials. An electrical charge is constantly maintained on the conductive layer of the screen.

When a finger touches the surface of the screen, it disturbs the existing electric field, which changes the electrical capacitance at that point. When a capacitive touchscreen is described as “multitouch”, it refers to the screen’s ability to detect multiple points of contact simultaneously. For example: pinching the screen with two fingers to zoom in, spreading two fingers apart to reduce the size of an image, making multiple taps to open an application, etc.

Finally, the term “projected” indicates the way the touch detection technology is implemented. A projected capacitive touchscreen uses electrodes located behind the surface of the screen, which distinguishes it from “surface” or “direct contact” capacitive screens where the electrodes are placed on the surface itself.

Capacitive Vs. Resistive Touch Screens: When to Use Which Panel

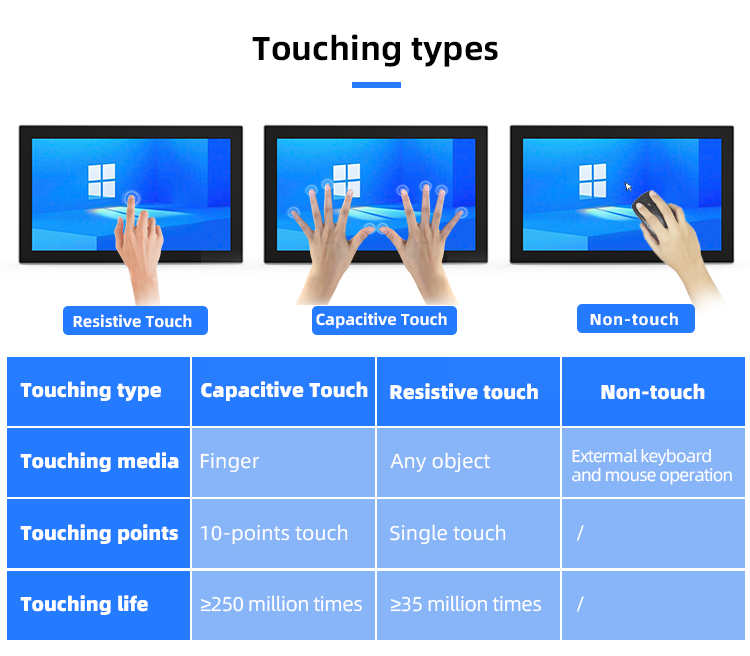

Resistive Touch, Capacitive Touch, Non-touch Three Type Compare

Resistive touch screens register touch by the physical tactility. Meaning, that it can detect touch from any object, regardless of whether the object sends electrical signals or not. Capacitive touch screens register touch through electrical currents, like our fingers for example. Here’s a breakdown of resistive vs capacitive touchscreen use cases:

1. Resistive Touch Screen

Resistive touch screens are great for devices where you don’t have to touch with your fingers. Things that operate underwater are a good example. Outdoor vending machines and ATMs often use this as well.

The downside to resistive touch screens is that they aren’t as accurate as capacitive touch screens, and are usually less durable due to the flexible top layer, which can wear over time.

2. Capacitive Touch Screen

Capacitive touch screens have excellent accuracy and are significantly more durable than resistive touch screens. Both types of capacitive screens are better than resistive touch screens in terms of accuracy, but the projected capacitive variant is much better than surface capacitive.

Surface capacitive touch screens are usually used in touch screen TVs and other similar devices. You’ll see these on smartphone screens. The latter is significantly more expensive, so people use surface capacitive for larger screens.

Conclusion

Hopefully, you now understand the mechanics behind resistive vs capacitive touchscreens. The key difference between the two types lies in their touch-registering capacity. The latter is more accurate than the former, but the former is cheaper and more flexible in terms of the things it can register a touch from.

In conclusion, resistive and capacitive touch screens each have their own sets of advantages and disadvantages. The appropriate choice is contingent upon the specific demands of your business operations. Resistive touch screens are budget – friendly and can be operated while wearing gloves, which is a practical advantage in some work environments. Conversely, capacitive touch screens are more robust and highly responsive. This responsiveness makes them particularly well – suited for applications that demand top – notch performance, such as in high – speed data – entry systems or advanced interactive displays. If you’re uncertain about which option to choose, it’s advisable to consult an expert. Such professionals can provide valuable insights and guide you towards making a decision that best aligns with your business’s unique needs.

High – Performance Displays Multi-Touch Capacitive Touch screens

COMPT Industrial Panel PCs typically feature high – performance displays

COMPT offer a wide range of industrial display sizes, from small 7 – inch screens for compact control panels to large 32 – inch or even larger displays for industrial monitoring stations. The displays are designed to provide clear and vivid visuals, even in bright or dimly lit environments. Many open frame panel PCs use advanced display technologies such as LCD with LED backlighting, which offers better energy efficiency and a wider viewing angle compared to traditional CCFL – backlit LCDs.

Among the touch – screen options, COMPT Multi – Touch Capacitive Touch screens are increasingly popular. These capacitive touch screens use electrical charges to detect touch input, They offer highly accurate multi – touch capabilities, allowing users to perform gestures like pinch – to – zoom, swipe, and multi – finger operations with ease. In applications like industrial control rooms or retail point – of – sale systems, touch – screen capabilities can significantly improve user experience and operational efficiency.

Penny

Web Content Writer

4 years of experience

This article is edited by Penny, the website content writer of COMPT, who has 4 years working experience in the industrial PCs industry and often discusses with colleagues in R&D, marketing and production departments about the professional knowledge and application of industrial controllers, and has a deep understanding of the industry and products.

Please feel free to contact me to discuss more about industrial controllers. sales@gdcompt.com