Types of Compt Fanless Panel PC

-

Stainless Steel Touch Screen Fanless Industrial Panel Pc

- Screen Size: 13.3 inch

- Screen Resolution: 1920*1080

- Luminous: 350 cd/m2

- Color Quantitis: 16.7M

- Contrast: 1000:1

- Visual Range: 89/89/89/89 (Typ.)(CR≥10)

- Display Size: 293.76(W)×165.24(H) mm

-

15.6 inch embedded industrial touchscreen fanless pc computers

COMPT’s new product is a 15.6-inch embedded industrial PC designed for industrial environments.It utilizes advanced embedded technology for stability and reliability. The computer is equipped with touch screen technology for easy operation and control.

-

10.1 inch J4125 fanless industrial panel computer with All in one touch embedded pc

10.1 inch J4125 fanless industrial panel computer with All in one touch embedded pc, packing all the power of a personal computer into a sleek, compact design. This device is the perfect solution for anyone who wants a complete computing machine that takes up less space, increases productivity, and provides a great user experience.

The All in One Computer Touch Panel PC also features a range of connectivity options including Wi-Fi, Bluetooth and USB ports. It also comes with a webcam and built-in microphone, perfect for video conferencing and video calling. The device provides high-quality video and audio output, making it ideal for both personal and professional use.

-

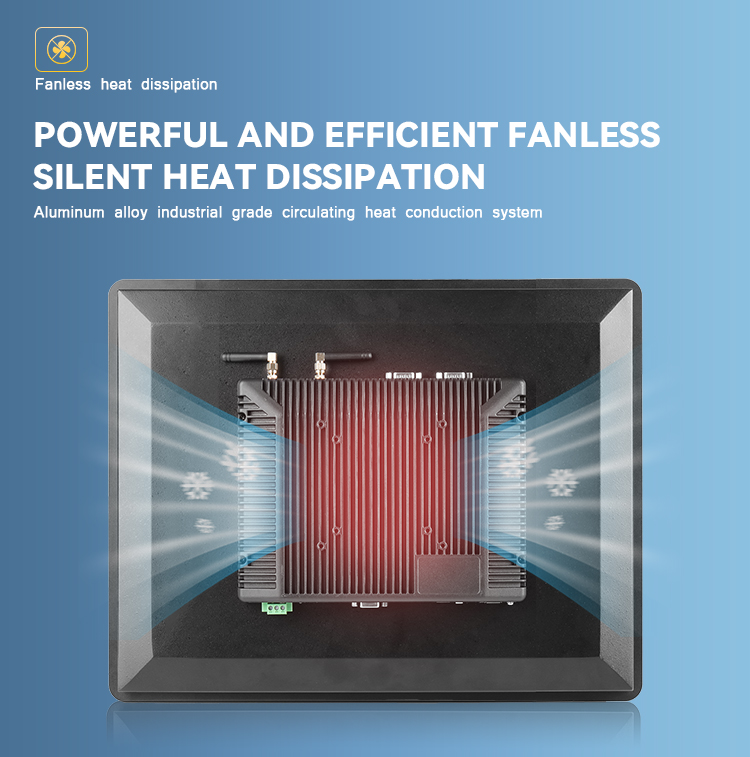

Fanless Industrial Front Touch Panel PC Computer Windows 10

Our Fanless Industrial Front Touch Panel PC Computer Windows 10 from COMPT is a product with outstanding performance that will bring a new experience to your industrial applications.

The Fanless Industrial Front Panel Touch Panel PC is a computer designed for industrial environments using advanced technology. It runs on Windows 10 operating system with rich features and a wide range of applications.

-

17.3 inch fanless industrial panel mount pc touch screen

17.3

Black

1920*1280

Embedded

Resistor Touch

YS-I7/8565U-16G+512G

PCBA three-proof paint

Active cooling

2*USB Expansion, 2*RS232 Expansion